Playlists Manage

Log in to create a playlist or see your existing playlists.

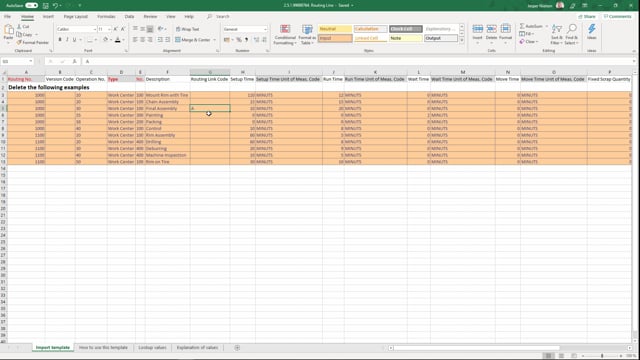

Log inHow to import routing lines with the Excel template for Business Central?

Routing in Business Central are set up both in routing header and routing lines and they are separate tables so they have to be imported separately.

This is what happens in the video

In this video, I will go through the Excel import template for routing line.

Before you import the routing line, you need to have imported the routing header.

So let’s go through the fields that we can import with the template.

First of all, if your field is marked with red, it means it’s mandatory or a minimal requirement for the system to work and if it has a grey background, it means it looks into an underlying table where data is stored.

So routing number that actually looks into the routing header that should be imported previously.

If you have a version on your routing and operation number is the way through the different operations.

So it will always go, it goes alphanumeric, it will always go from 10 to 20 to 30 to 35 in this case or ABCDEF.

So that’s the way through the routing.

We have the type, in this case, it’s a work center and we can see its underlying table so we can go into the lookup values and we can see that you can choose between work center and machine center.

And we have a number and the number is referring to, in this case, the work center.

We have a description of the point of the route and we have a routing link code.

In this case down here, we have a routine link code marked with an A and that is combined with the BOM that we have the bill of materials.

So actually this one says that on this point in this route, we should use the items that are marked in the bill of materials that are marked with the routing in corresponding link code A.

In that way, we can have a lot of our items on stock for a longer time.

Set-up time is once you use that so it’s a setup time for the whole operation for once and then you can run far as many minutes as you want.

In this case, it takes 110 minutes to set up the mount rim with tire route point.

Runtime column, times it does take to get through one operation.

Wait time, do we have to wait between the tasks that we do on the same work center.

Move time, the time for it to move to the next operation.

And of course, in all these, we have the wait time unit of measure code, we could also see that in the lookup values.

We have the fixed scrap quantity.

We have a scrap quantity or a scrap factor on each of our steps in the routing.

Concurrent capacities, how many simultaneously operations can run on this workstation.

Send ahead quantity makes it possible for you to send some of your finished item on to the next step in the routing before the step you are working on is finished.

So that can minimize the time through the whole routing, for example, you can send half of your items onto the next step in the route.

If there are additional costs for the step and if you’re working with lot size.