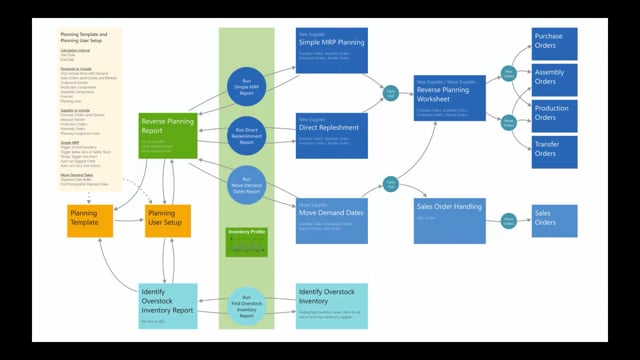

This is a nice little picture to explain how reverse planning works, the logic of it, and I will run through it shortly just to give you an overall understanding, and in other videos I will show you more specifically on the details of it.

So let’s look at it step by step.

Basically we have four or maybe five different areas.

The simple MRP planning and direct replenishments are both to create supplies, to create new supply and only new supply supplies so it doesn’t change anything, it doesn’t replenish anything, it just creates new supplies.

But it’s in two different paradigms and it does two different things, one of them being more complex, the simple MRP, the direct replenishment basically does the same but it’s wrapped in a simple understanding so it can be used for many different purposes.

Move order dates is to move demand dates when it doesn’t get better on the supply side.

So you want to move demands which is not possible and find those demands.

The identify overstock inventory is a functionality to find items that has too high inventory values that expires if you want to run expiration date handling.

Or maybe you have some supplies that you don’t need anymore and we want to find those even though they are either locked or we cannot find them in the normal planning functionality.

And then the fifth one I talked about, we also can do some nice forecasting functionality, but it’s not part of this explanation here.

The first three examples here, the simple MRP, direct replenishment and move demand dates use the same core report that we call the reverse planning report.

It has some different fields when you run it, so it uses different functionality, but basically it uses the same engine to calculate.

The identify overstock inventory functionality has its separate report, but they all use the same core inventory profile functionality.

It’s the same logic that we use in our graphical inventory profile and other apps like assign quantity, flexible forecast.

So we have a deep core logic on how to calculate that inventory profile.

New supplier orders are made in the simple MRP planning or direct replenishment and when you carry out from those it’s transferred into the reverse planning worksheets which is similar to a planning worksheet in standard business central or a requisition worksheet and from there you can create purchase orders, assembly orders, production orders and transfer orders as new orders.

The difference from a standard planning functionality is that you only create new supply orders.

You don’t suggest changes, you don’t suggest rescheduling or changes quantities or canceling, only new supply orders.

Whereas the move demand days functionality, when you carry out from that journal, it will move some of the lines into the reverse planning worksheet if it’s trying to move assembly orders, production orders or transfer orders because those can be handled with a lot of standard business central functionality for moving dates so it will be only creating the action messages that we know as rescheduling whereas sales orders will be moved into a sales order handling journal that we created in this app where you can see all the sales order that needs to be moved and from which day and to to what date so So the moveDemandDate functionality is for moving demands that is not possible.

And the overstock inventory functionality is to find inventory with too high value, which has safety stock multiple by whatever you set up, and there’s a lot of way you can set up to find item that is too high on inventory.

You can also identify item that expires or has remaining shelf life percentages, maybe item item you want to sell out.

So if you have set up an item that you want to get rid of, you can find them in here and see how many you have left that you need to get rid of.

And this is all made with planning user setup and planning template logic where you can set up templates that is a default setup.

We have a lot of default setup and you can set up a planning template that relates to your complete company.

So everybody uses the same planning templates.

When you select the planning template, it updates your planning user setup, so you can also make your own setup that is specifically for what you want to use.

Those two are by default, and you can set up your own many templates for the company that you want to run.

That could be different template for different purposes a year.

In a total, this is how reverse planning looks when you look at all the logical functionality.

This is how reverse planning looks when you look at all the logical functionality.