In this video, I will show you how I can plan for transfer orders first on my main location and then for production orders and then for purchase orders all in one go, all in one step in Business Central.

And I’ll do that in my simple MRP to provide you an example here.

I have some different locations that I’m selling from my shops and I want to calculate first from those locations and then from my manufacturing and then for purchase.

And I’ll show you the result first and then afterwards how I did it.

And it’s all based on this template up here that I’ve selected.

So I’m looking into the template here.

I’ll select it from the template list and I’ll get back to what it actually did and the setup in here.

And all those locations here are coming from my template and this means I want to plan on Copenhagen, Aalborg, Newburgh, Hamburg, VMS Center.

Those are the transfer location that I want to plan production on my production location and then purchase on my production location.

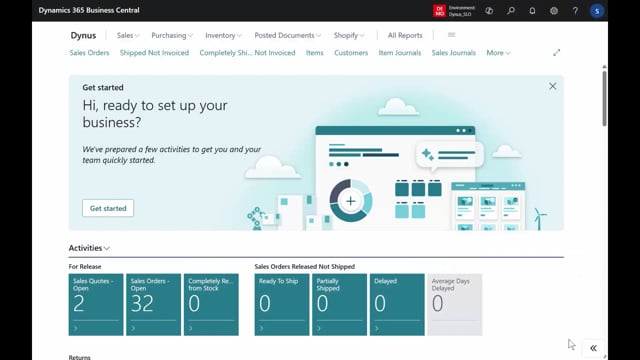

So now it’s breaking down everything putting it into my reverse planning journal and my simple MRP journal here is empty because it’s all transferred into my reverse planning worksheet in here.

So when you look at this one now you can see they are all suggestions for new items.

In the beginning you can see from my different locations where I have demands.

I have suggested quantity with order multiple or safety stock.

They are all transfer orders moving from transfer code production.

If I scroll down I can see I have my production order.

What do I need to produce? Of course only the items that I lack and then my purchase orders that I need to supply.

This provides me a very nice overview and in here I can accept action messages and start carrying out.

What actually happened is this.

I went into my calculate simple MRP.

I selected a template and we have those three templates here out of the box with the standard set up except I modified some of them.

So the first one being I want to transfer orders to transfer orders to safety stock then production orders then purchase items and if you scroll a little right you can see here I’m using both the auto run functionality meaning I want to start planning transfer orders to safety stock I want to automatically run suggest quantity to order with the template that is written in here and I want to carry out action meaning it transfer those into the reverse planning journal.

And when I’m done, I want to run the next template, production orders to safety stock, which is the next line, and basically does the same, except for the filters.

And when I’m done, I want to plan the next template for purchase item.

And this way, you can continue building as many templates you want to run in one go.

And if you scroll right in here, you can see I have my suggest quantity template that could be first for all of them.

So in here I stated, I just need to edit my list, I stated in here when I suggest quantity in here, which date would I do it on, rounding up and down.

I can see here what is my item filters and do I have a SKU filter.

So on the first line I had a item filter for all transfer items and you cannot filter that on the item cards.

In real life, my filter on the item filter here is only that the type needs to be inventory and block needs to be no, whereas the SKU filter that I’ve created in here saying only transfer orders, if I’m looking at that one, I created a filter here that the replenishment system needs to be transfer and here’s all the location you saw that it default suggested on that first template.

On the next two templates, my production orders, I’ve added some other item filters.

So on the first one, which is all my production items, I said type inventory, block no, replenishment production order, and only on location production, which is my main location.

And likewise on the last one for purchase items, on my main location production, but only for purchase items.

So planning and you can set up different planning parameters per iteration.

So if you look at the Transporter, of course, it will have its own planning template card.

So if you show this one, you can define for that iteration exactly all the parameters it needs to include.

So this is a very agile way of setting up iterations of planning that you can use.