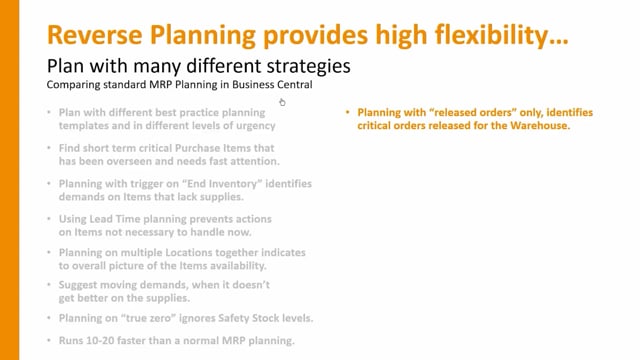

With reverse planning, you have lots of flexibility and you can plan with many different strategies.

And in this video, I’ll just run through some of the most important comparison between reverse planning and standard MRP planning in Business Central.

So let’s look at some of the most important features in here.

First of all, you can plan with different best practice templates that comes out of the box and you can plan in different levels of urgency.

And I’ll just show you quickly what it looks like in Business Central.

If you enter the reverse planning, the for instance, the simple MRP planning like this, and you calculate simple MRP out of the box, you will have some templates in here.

And in my scenario here, I have templates for both blank and manual, and I could have added even more in here.

So if I wanted to, I could also add a template for direct replenishment.

And as you can see now, my list will be even bigger in here.

But the point is for each template, you can define many different parameters.

So there’s lots of flexibility on how to plan in different levels of urgency.

That’s the planning templates.

Second thing is you can find short term critical purchase items or even production or transfer items that has been overseen or needs fast attention.

So one of the first templates is a template to find stuff that goes below in the inventory, which are critical.

And this means you can also plan with a trigger on in the inventory that demands identifies that lacks supplies on the end inventory and not in the period you are planning.

Let’s take a look at what that might say.

So if you take the first template here, which is called find critical items below zero on end inventory, what it does is that it selects zero as a trigger on end inventory level, it triggers an end inventory.

And this means we don’t care if we go below safety stock in the period.

So we’re actually only triggering on the physical end inventory, not the lowest inventory.

So all the items that was below safety stock, but as a positive end inventory, which was just above zero, didn’t show up here.

So those are the ones we need to handle first.

And this way we can plan in different levels of urgency.

We can also use lead time planning, which means we can prevent action for item that has a short lead time.

So instead of planning everything within the same time frame we can set up what we call lead time planning this is if we look at some of the templates in here i think i have a template for for instance my outbound transfer demands here if i look at this template card instead of having a fixed default start date formula and end formula i would like to plan within lead time and then add 20 percent just multiplying by 1.2 and adding one week on top of it.

So an item with a long lead time, I will plan in a long period.

And an item with a short lead time, I will only plan for a few days in the same batch job.

So this makes it more flexible and I don’t plan quick replaceable items far in the future.

You can plan on multiple locations together.

So instead of planning per location, there’s actually a checkmark where you can say, I would like to plan on several location in like in one big bucket.

So if you have maybe shops that you’re selling from, you can see is it across location, is this item critical or not? That’s a check mark called plan per location.

And of course you can suggest moving demands when it doesn’t get better on the supplies.

This is one of the other main areas of reverse planning here.

If we go back to the main menu, we have the move demand dates functionality and this functionality is just to suggest moving demand dates when it doesn’t get better.

So instead of with the standard MRP planning creating both new suggestions or suggestions for new orders, moving orders, changing orders, cancelling orders, with this functionality, we only create either new orders or move demand dates.

As I showed you before before we can plan on true zero which ignore safety stock levels so it’s actually possible to plan on actual zero items that are actual critical or you can plan on safety stocks that’s a selection you can do whether to plan on zero, safety stock or reorder point so you can plan again on different levels of urgency and the MRP planning is running 10 to 20 times faster than normal MRP planning because it’s not an iteration, it only suggests the items that you need to handle.

So it’s not as smart as an MRP planning, but it’s more flexible and more simple to use and get started with.

And it actually works very nice together with the MRP planning.

You can select on which supplies and demands to use to identify your critical items.

Let me show you what that means.

So if you’re in a planning here in a template, let’s just take a look at one of the templates, maybe our critical items here.

If I look at my template card, what we are planning for, there’s a full selection here of which kind of orders would you like to include all sales orders, only release sales orders, which type of production orders, which type of production order components and production orders, would you like to have all purchase orders? So there’s a lot of setup that you can determine only to include some suppliers and some demands.

And as I said, in the simple MRP, we only create new orders and in the move demand dates, we only suggest moving demand dates.

So it’s more simple to do either one or the other.

You don’t get many lines in the standard MRP journal that you have to handle in one go.

And then you can find overstock inventory to identify too high inventory bindings or supplies that you need to cancel.

So whereas the normal MRP would also have actions to cancel orders, we would do that with what we call overstock inventory to figure out items that are too high in inventory, items that we need to supply, we need to cancel, or maybe items that we need to sell out because we didn’t sell as much as expected.

And it doesn’t require any setup to get started with the reverse planning.

You can just download it from AppSource and you’re up and running in 10 minutes.

So all the templates are coming out of the box with best practice setup.

You can change them as you want, but they are working just out of the box.

And we have a check mark where you can select whether only to plan on item that exists on demand orders.

So if you place this check mark and you have many items number, it reduces the planning time a lot because it will start by looking if the item exists on one of the demand lines, transfer orders, sales orders, production order components, assembly orders, and if not, then it would just skip the item.

So that saves a lot of time.

Then you can use the reverse planning to break down a long term sales forecast.

So if you have a sales forecast for next year and you want to figure out what are the consequences on the purchase side or the production side or capacity requirements, you can use reverse planning to do that calculation so you can give an estimate or budget or even a purchase forecast to your vendors.

And the planning templates that we have that I’ve been showing you a few times in this video can be configured to almost anything you need.

So the planning templates have lots of different setups, so you can do your own planning templates, copy one of the existing or just create your own one from the beginning, and then set it up to do exactly what you want.

So those are the most important differences between the standard MRP planning and the anyone.