Install the reverse planning app, you might want to calculate low-level code and rolled up lead time if that is not already in your system.

The low-level code and we have different videos to explain that.

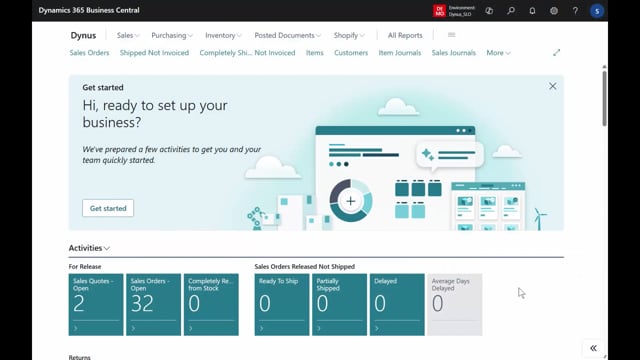

If you go into your manufacturing setup, this is only if you use manufacturing production orders, you can see here the field dynamic low-level code.

If that is checkmark, you might have the correct low-level codes already and we have a separate video explaining what low-level codes are.

This is standard functionality, but if you import data from other system or you upgrade it, this might not be correct.

In standard Business Central, you have a functionality called calculate low-level code, and you can run this one.

If you calculate it, if you select this one, it will run through your item and build the Bump Tree on all the items which is not calculated.

It might take some time, so you might be aware when you do it.

The second thing you want to do is in the simple MRP, we have a functionality where you can use from and to date, or you could use rolled up lead time.

This means if you look at an item, if you just calculate normally, you can set, I want a start date and I want an end date, and that will be the MRP calculation for all your items in that period.

But maybe you want to calculate specifically in a period from a lead time or what we call rolled up lead time per item, so the item with small lead time gets a small calculation interval and the item with long lead time or long rolled up lead times is calculated further to make sure you get the supplies correct.

And you need, before doing that, you need to calculate the, in here, calculate rolled up lead time.

This report can take quite some time because it can run from all your location, all your items, so therefore run it when the system is not too loaded.

And once it’s done, you can go in and look at them in the rolled up lead times in here.

So for instance here on my item 1000, when I produce it on my location production code, and it’s a production item, it might be a transfer item on other location.

You can see here when I produce it, it has a lead time of 14 days according to the routing, direct lead time, but a rolled up lead time of 36 days.

So if I’m going to supply everything below this item in the hierarchy, it takes me 63 days, whereas when I transfer it, it’s only one day.

But the rolled up lead time, probably because I’m transferring it from the production location, will be 64 days, of course.

We have other videos explaining this, but you might want to run those two jobs, the calculate low-level code, the standard, and the calculate rolled-up lead time in reverse planning.