One of the issues with reverse planning or one of the ideas of reverse planning is that you can calculate to move the demands when the supplies doesn’t get better.

In my example here, I already calculated a full MRP planning.

Everything was good and everybody was happy.

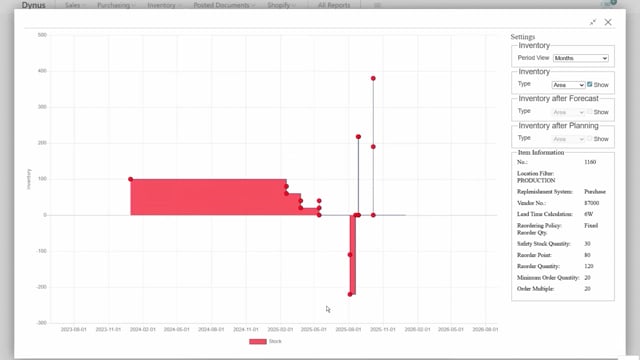

But on my item 1160 down here, my tires, which are here, my vendor called me and said, we have an issue.

And there was a purchase order here with a date, which was August 5.

And he said, we can only ship this or deliver this on August 20 instead.

So this purchase order is hidden somewhere in here from supplier Ying in Shanghai, 20 years of August instead of the 5th of August.

Now, if I look at the planning worksheet, Standard Business Central, and I recalculate this one before the movement, everything was good and nothing happened here.

So my planning worksheet was totally blank.

Nice.

But now I would expect it to move or cancel or create, reschedule this item because we need it on August 5, as just explained.

The problem is I cannot move this order because I called my vendor many times already and he said that’s not possible.

So what I need instead is a functionality to move my supplies, move demand dates in here, and I can suggest moving demand dates, which calculates low-level code up.

So it starts with all the purchase items, then the lowest level code of production items, transfer items, assembly orders, etc., etc., up to the sales order.

And here I can see that it needs to move the due date, which was August 14 to 1st of October on the two production order here.

So there’s some lead time on this production orders.

If I view my supply changes on the first production order, this is farm plan production order here.

We need to move this because of my item number.

So due to this item, I need to move that production order from one date out here to written out here somewhere.

Due date here that I recognize to a new due date order.

And because of those two changes, it’s the same on my front wheel because of those two changes it accumulates up through the hierarchy so i also need to move my city bike to all the lines here and my sorry the city colibri bike and my city bike they also need to be moved and they are all production orders so the those will all end up in my reverse planning worksheet when i carry out so if i check mark everything here and say yes please change all this carry out actions it will be moved into a reverse planning worksheet and it will all have the actions rescheduled to postpone the production orders.

Since no sales order showed up in here on the list I know that no sales orders is harmed by this otherwise they would have been suggested here in my suggest moving demand dates as well.

It would also have found the sales order and showed which sales order lines we were supposed to move.

But this is the whole idea of moving demand dates when the supply doesn’t get better.