Tags

Videos tagged with "Beginner"

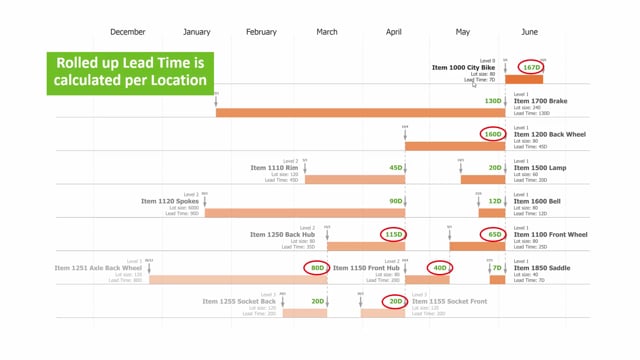

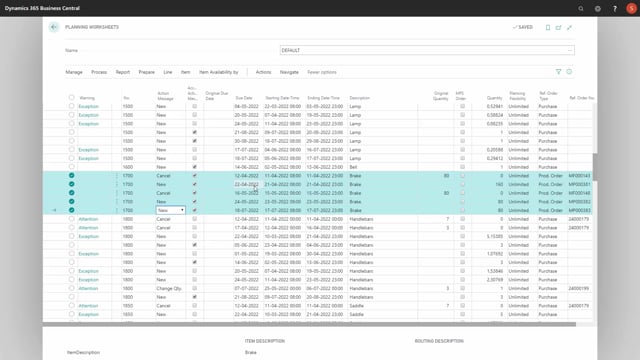

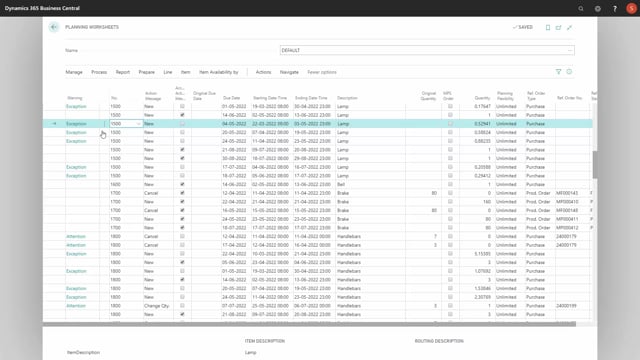

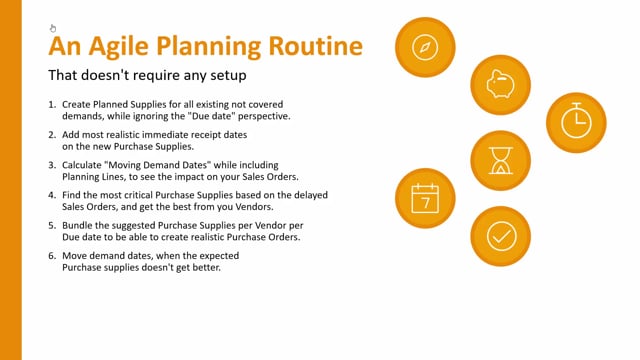

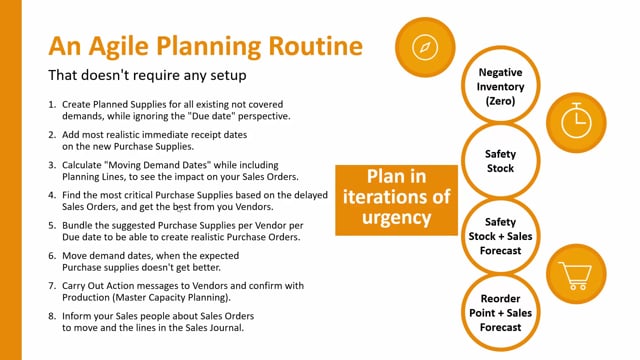

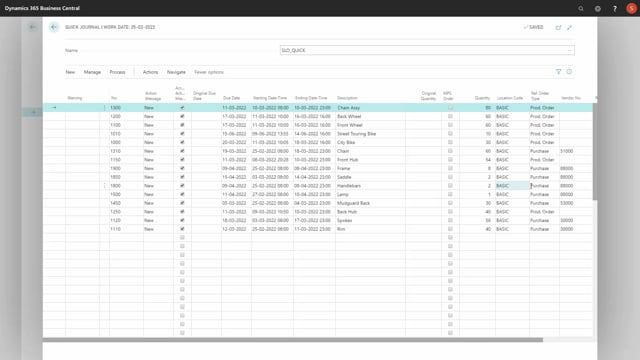

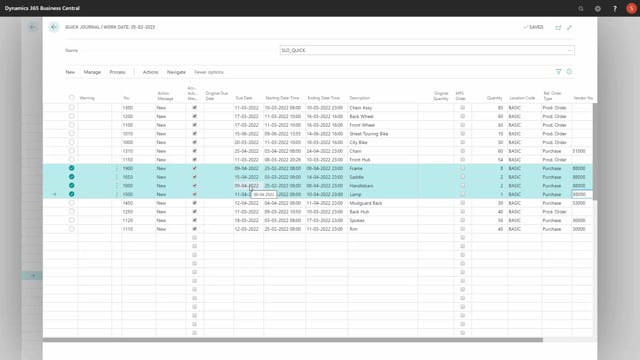

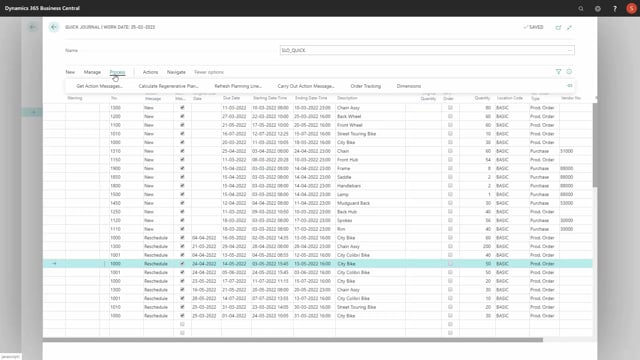

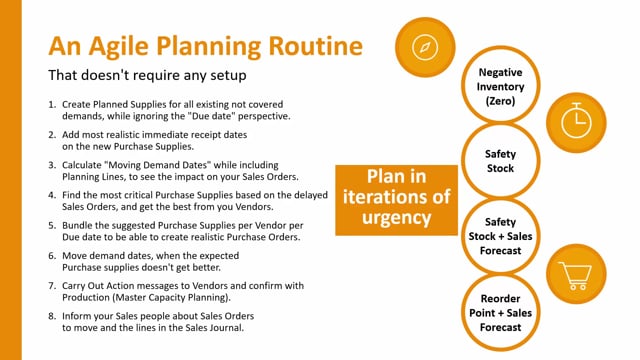

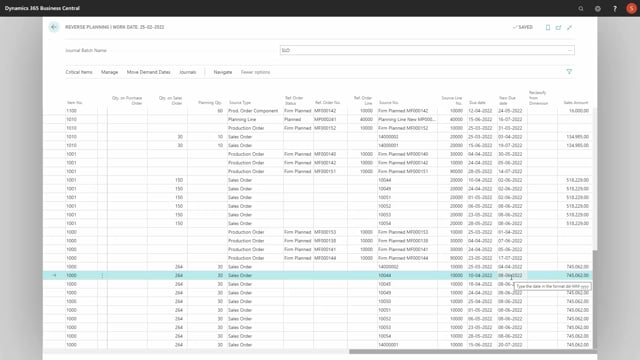

Step 1: Calculate Planned Supplies for all existing not covered demands, while ignoring the “Due date” perspective.

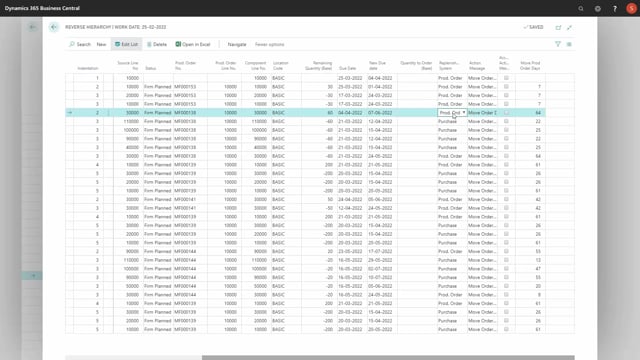

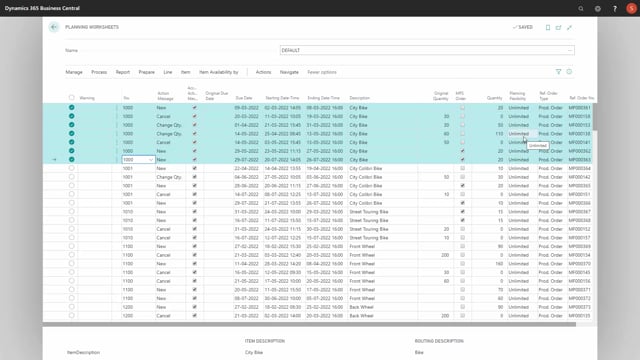

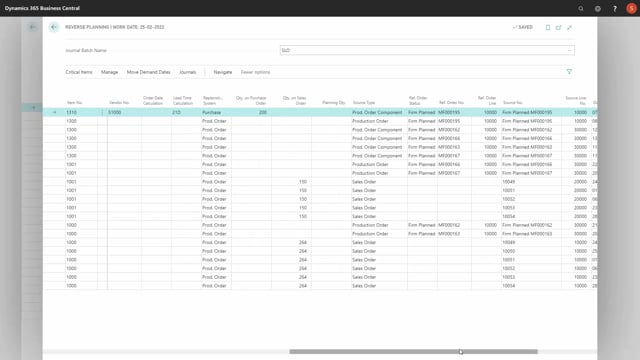

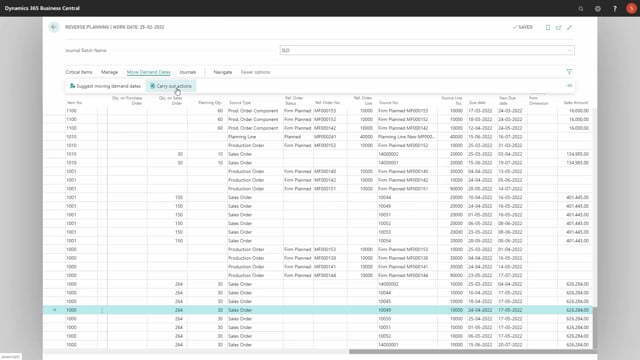

Step 3: Calculate “Moving Demand Dates” while including Planning Lines, to see the impact on your Sales Orders