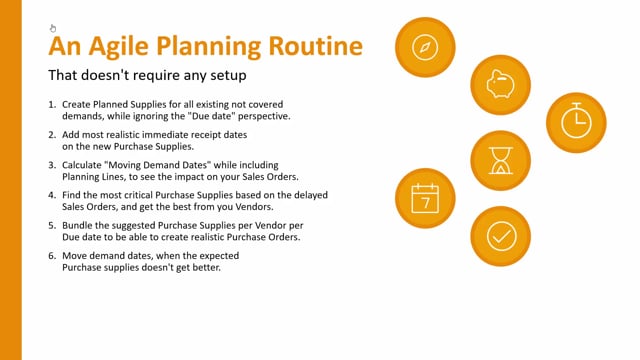

Let me introduce the Agile planning routine and show very shortly how it’s working in Business Central and then in other videos I will go into details for each of the steps.

Let’s see how it works.

First of all, step number one, create planned supplies for all existing not covered demands while ignoring the due date perspective.

This means from the Reverse Planning I would need to break down everything that has no supply and therefore I will calculate critical items and depending on the iteration I am in I will do this on zero level or safety stock level and including forecast or not.

So, in this scenario which is most critical I will not include forecast and calculate according to zero on one location and since it doesn’t break down the hierarchy structure I need to do this as many times as I have level in my hierarchy.

I suggest quantity to order, maybe using order multipliers and change the action message and carry out the orders and this will create lines in my quick journal in here and now due to those items that has components on those line it will create new lines when I run it again.

So, I will do the same step and again suggest quantity to order and I’m suggesting up to zero because this is the most critical iteration I’m running and I’m changing action messages and carry out orders.

I have to do this until there’s no more lines and instead of doing like I’m doing here I could just check mark the two how to run suggest quantity and how to run create orders meaning it will calculate, enter the lines, suggest quantities and move the lines into the journal.

So, I’ll just run this a few times and I think I’m done now and to test it we can just remove the two check marks to see if we have more lines in here.

And we’re done.

So, now everything is into the quick journal everything that we need to do all the items we need to handle but the dates are of course a mess.

Let’s look at point two.

Second, we would add the most realistic immediate receipt dates on the new purchase supplies.

Let’s do that in Business Central.

So, for instance on some of my items I will look at the purchase items in here and look at the dates and maybe this one is not possible to get before 12th of April like this and maybe another line up here instead of in March and I’ll have to contact the vendors or just to add the immediate dates that I think would be possible for those items if I know my vendors and this way I’m entering whatever changes I believe will be on the dates.

Just write immediate.

Let’s look at step three.

So, now I can calculate moving demand dates while including the planning lines to see the impact on the sales orders.

So, back in the Reverse Planning journal I could now suggest moving demand dates in here and I need to deselect the trigger on inventory and this will if I’m including planning lines that I am I’ve checkmarked the include planning lines functionality it will run through all the items calculate how to move the sales orders to get in a view on everything that I need to move to make it possible and if I scroll down I can see my sales orders in the end my top level orders down here meaning all those sales orders probably need to be moved from whatever due date here.

So, new due dates.

Looking at the sales line that it wants to move I can see for instance it wants to move a sales order from 10th of April till 8th of June and I need now to discuss with my sales people if this is okay or this is a big issue and maybe they say this is too much we need to do something and this brings us to next step.

So, the next step will be to find the most critical purchase supply based on the delayed sales orders and then to get the best out of our windows.

Let’s go back in Business Central.

So, from the sales order that is delayed we could navigate into the hierarchy of items that are delayed all the delays in here and in this hierarchy I could filter on purchase items trying to find the purchase items that are most critical with the late days for instance this one is the late 61 days and I do have other purchase items that are delayed quite as long let’s try to look.

So, I’m filtering on my it’s still production components that it wants to move but it’s purchased items used for production component and if I’m looking at the three ones with the most delay and I scroll left I can see it’s actually the same item.

So, thereby it’s possible for me to find the purchase items that are due or causing the biggest delay on the sales orders.

So, now I need to do at least something about those items.

So, if I enter my Quick Journal and I can find the item if it’s in here I need to do something about it if possible or if it’s not in the Quick Journal then there’s already orders existing orders on this item and I need to handle that because that’s the most urgent item.

So, I’ll need to talk to my vendors and see what we can do to make this better maybe we could fly it in and then if we are flying in it let’s say we can get it on another date here.

So, we will optimize the delivery date on the purchase sites.

Let’s take the next step.

So, next when I’m done with all the critical purchase items I will bundle the rest of the purchase items per vendor per due date to create realistic purchase orders.

This means when I’m looking here in my planning worksheet maybe all the lines for the same vendor here has the same date that would be very nice of course but if if they don’t have the same date like this on vendor number 30,000 I might want to bundle those two because it’s not realistic that I’m getting two items from the same vendor within a six date interval and therefore I will change the date to be more realistic per vendor.

I’m doing this in the Quick Journal.

Let’s look at the next step.

Step number six now I can calculate moving demand dates with the new expected purchase supplies that doesn’t get better and that I have bundled to see how it looks on the sales orders.

So, I would now delete all my suggested demand move because now I need to calculate it again or it will be calculated deleted when I calculate it actually.

So, I will calculate suggest moving demands again and still include all planning lines.

So, I’ve checkmarked the include planning lines and therefore it takes into account the new changes I made on the purchase orders and therefore I hope my sales orders are getting better than June 8 that it did just before.

So, if we are scrolling down to my sales items again down here and we’re looking at the new due date now we are back on May 17 which is the best we can do.

So, this is what we need to suggest our customers.

Let’s look at the next step.

Next we will carry out action messages to vendors and confirm with production and if we’re doing master capacity planning this is where we need to do it as well.

This means first of all we would like to actually suggest everything that the movement did in here.

So, all the suggested movement will be carried out meaning we are creating sales order handlings and we are modifying the existing quick journal.

The existing quick journal.

So, this is the sales orders to move and here we have the quick journal now with all the reschedules that we need to do on existing orders and all the change date on the purchase orders.

So, this is our action that we need to carry out now.

So, we need to order the new purchase items and we need to move all those production orders in here.

And if we’re doing master capacity planning this is the time to figure out if the production can actually do this on the date and of course if the production can’t do that we need to change the date on the production orders as well to make sure the capacity planning is okay and then recalculate the movement of sales orders once again.

So, from in here when we’re all ready we will proceed and carry out action messages to firm plan orders, assembly orders etc and create all these orders in here.

Meaning that we are sending the mails to vendors, updating the production orders or assembly orders if we have those and transfer orders etc.

So, this is now the plan being carried out from the quick journal.

Let’s look at the next step.

So, the last thing would be to inform our sales people about the sales orders to move and the lines in the sales journal which means that my quick journal is empty in here but my sales order handling contains all these lines and I need to hand those over to the sales people asking them to move this date for the customers because this is the realistic date that we can actually do and if I want to control that everything is correct I could calculate again for critical item and hopefully nothing should pop up looking for critical items.

It should be empty and when I move demand dates in here, suggest moving demand dates and I include sales order handling and I need to do this without the checkmark.

It should also be empty because I included the sales order handling lines.

So, now I’m all done. My planning both critical and move is empty and I can go to lunch.