Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inOf course you could discuss what a real critical item is, when is an item true critical and there’s a date issue in that and there’s a replenishment issue in that. So if I’m calculating in my Reverse Planning and I place a checkmark in the calculate according to zero, means I will only see the lines that goes below zero.

And if I place a checkmark in the trigger on end inventory, it means I will only look at items that actually has an calculated inventory below zero on the end date of my calculation. And if I look far enough ahead in this scenario, a year, I will find all the item that needs replenishment, meaning I need to do some kind of supply orders for those items.

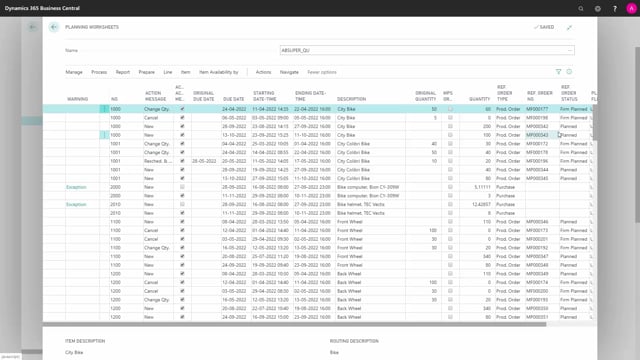

And that’s the most critical item I would say. So this scenario, I only have one item that actually need to purchase all the other items I do have somehow, but I need to reschedule some dates. This is a very strong tool because normally if you go, let’s take in this scenario just to try it out in a planning worksheet. So this is a standard MRP worksheet.

And if I prepare my plan in here for a full year in the same filters and not including forecast, because I didn’t include forecast in the other calculation, whereas I only have one item that I actually need to replenish when somehow my planning worksheet will create much more line and therefore it’s much more difficult to overview which vendors I have to contact right now to get my item in stock. Or maybe it’s not right now, but it’s at least the orders I need to do.

So in a true live environment, I would set this calculation one week ahead from today, looking from only the next five or seven days, calculate on end inventory, and I’ll find the actual critical items. As you can see, it’s a lot of lines in the MRP worksheet, maybe even hundreds of lines. So finding the end inventory, negative end inventory, should be the first item I should handle.