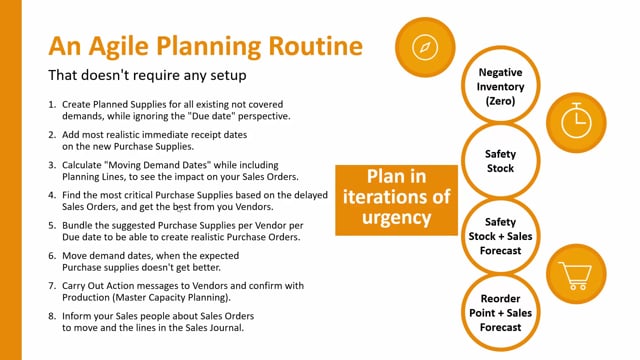

With the Reverse Planning it’s possible to use this agile planning routine to follow eight steps to make your plan being more or less perfect but you need to do that in different iterations of urgency.

So, the first one will of course be to calculate up till negative inventory or inventory below zero to make sure that you have no critical items.

Let’s see how this could look when we’re done in Business Central.

So, when I’m done with all my planning here and I calculate for critical items using zero and trigger on end inventory no forecast etc.

It should be empty when I’m all done and when I suggest moving demand dates it should also be empty.

Then I’m done and I can continue to the next step meaning for instance I could calculate up till and I can do that after lunch I will calculate up to safety stock in zero but still with end inventory.

So, now I’m triggering on items that has a safety stock level that I need to fulfill.

So, those are all not critical related to and zero level but they’re critical if I look on safety stock and I can plan with this with all eight steps in the planning routine looking at safety stock and making sure that all items are okay.

And of course when I create orders for these items in this scenario I have my item 1310 and if I have suggested quantity to order in the first iteration in a more smart way I could have calculated not till zero level but maybe up to reorder quantity.

So, actually I could do this while still having lines in the quick journal.

So, I’m maintaining the lines in here instead of first making purchase orders for the vendors and then making new purchase orders up to reorder point I could modify the lines in the quick journal running this functionality.

And later on when I’m done with all the safety stock item I could continue maybe including forecast or even up to reorder point etc and it creates more and more line but they are less and less critical.

So, let’s look in PowerPoint how those iteration could look.

So, from here first of all calculate negative inventory then per safety stock and then maybe safety stock and forecast and reorder point etc.

So, you need to define those iteration what makes sense for your company and depending on the time it takes you might want to leave the line in the planning or the quick journal until you’re done.

So, you have the best purchase orders.

But if this is a process the eight steps if it takes two days or one day for you you would have to order the purchase item for the critical items and then handle safety stock and reorder point items later on.