Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inOne of the classical issues using standard MRP planning is that it only calculates backwards from supply and it doesn’t calculate the other way.

So, if we are in a normal planning worksheet, and let’s say that everything is planned correctly and in many iterations,.

So, we’re all done and everything is nice.

So, when I calculate the full plan on many items, in this scenario, all items, it will only suggest new lines for one item because we only miss or we only lack one item.

But maybe those two dates are not possible.

I’m talking to the vendor and the vendor tell us we can deliver this one in May first.

So, I’ll just collapse those two lines and make it 160 in total and delete the first line.

So, this is what is actually possible.

So, let’s create this one line, send it off to the vendor to create it as fast as possible.

Now when we calculate the MRP plan again, and we are calculating for all items on this location, the only thing that will happen is that it will recalculate or re-suggest to move this purchase line because the mathematics says that we need it on April 4th and April 27th, even though we know it’s only possible to ship in May 15 or to get in May 15.

So, this is one of the issues on the MRP.

It calculates only backwards, even though this is not our reality.

So, this is not the thing we could do.

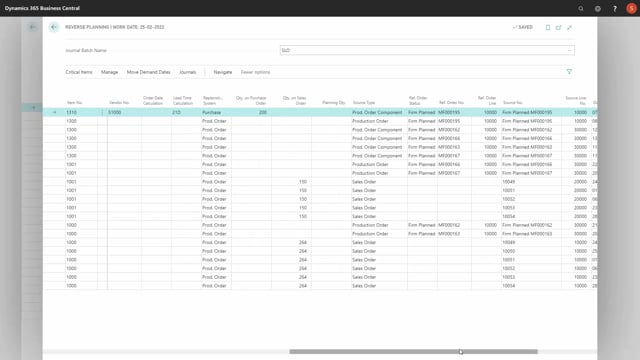

So, using the Reverse Planning, it would have been possible to see the actual consequences instead.

And that’s what we need as an extra tool.

It’s like the opposite MRP.

So, we can suggest to move demand dates now that we know that one item is not available at the time that the MRP suggests.

And actually these are suggestions for everything that we should move according to this lack of this one purchase item.

So, this is one of the classical issue with standard MRP planning.