One of the main ideas with the shortage on demand orders is to avoid partial deliveries if it’s on sales order and if it’s in production order, it’s to make sure you can run the full production order without having shortage on the production order.

This is what happens in the video

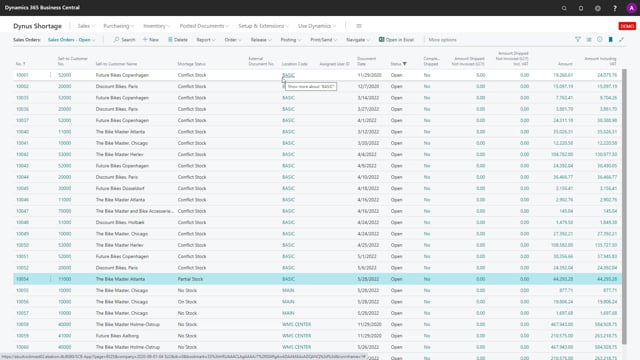

This means you calculate and then you can see if the orders has a status of no stock or conflict stock.

Meaning you can ship the complete order without having partial delivery.

So it’s a tool to make sure that everything you send has no partial deliveries, and thereby you save money on the freight and it’s easier to set the expectation with the customer if they can have the goods or not.

So it creates transparency for the salesperson and the warehouse people.