When you use Assign Quantity, the system will always try to find the best suitable match for all of your customer in the order you enter the sales order.

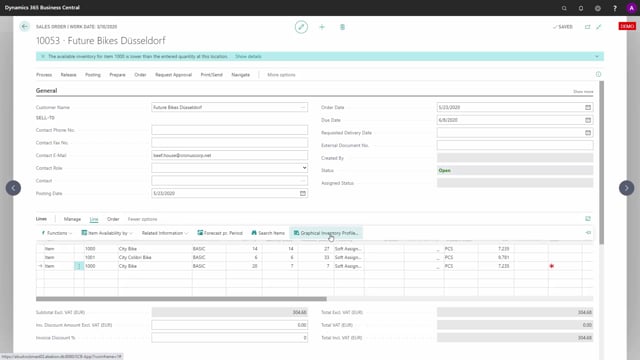

This means if you enter a sales order line like this, with an item number 1000, item number 1000, and I enter the date out here, let’s try to do that.

And we’ll take a date in March 25, like this, and enter quantity of 20.

And it will now assign seven pieces.

And if we look into the graphical inventory profile, which is a free app to try to explain what happens here on the line, and we look at all the demands, what actually happened on this date, we enter the sales order here on March 25, like this.

And theoretically, we will go to minus eight on inventory.

But if you used normal reservation, and you will have reserved supply and demands against each other with standard Business Central, you might have some of all those demand here being reserved up to the supply that were before those demand.

So, it’s very complex to unlock all of those reservation and make sure everybody gets what you promised them.

In this scenario, it just calculates mathematically what is still remaining possible on inventory.

This means, if we look at the inventory profile, only with the assigned quantity that we made.

So, I’ll checkmark this one just to see the inventory profile, including the assigned quantity, we can see here that we only assigned seven on this sales order, due to the fact that within the two month period here, we cannot accept to go below zero.

And there’s another sales order out here triggering inventory to be zero.

So, it actually calculates what is possible, and it does the best possible thing mathematically.

So, this is the way the assigned quantity tries to figure out all the best match at all times.