Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inWith the Assign Quantity, it’s possible to reassign to all sales orders, for instance, if you get new supply orders.

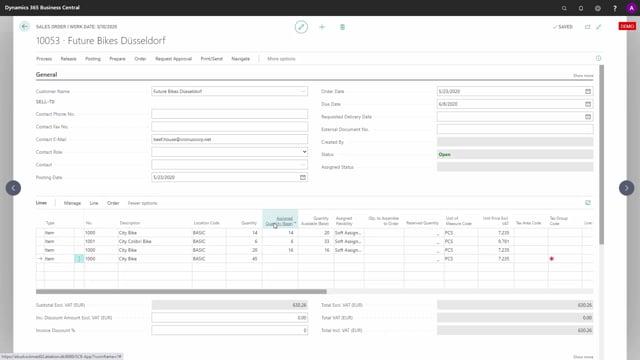

So, in this example here, on many sales order lines, we have the same item number in different sales orders.

In this one, we have three lines, but also in other sales orders, and we can see some of them haven’t been assigned because we do not have enough quantity.

If we look at the graphical profile to help us without the assigned quantity, we will see here that there’s a lot of inventory missing.

We are below zero in much of the time.

And of course, they are not assigned because we can’t promise what we don’t have.

So, if we look at the inventory again, with assigned quantity, it shouldn’t go below zero, if the math is correct.

Now if we assume that we would like to actually supply more than what we’re doing now, we will try to change our supplies, call the manufacturing if we are doing production, or call the vendor if we are purchasing the item, and maybe it’s possible.

So, in this scenario, we know we have a firm plan production order.

I would just change the firm plan.

It could also be a new order, of course.

So, this is supply on four pieces on the 20th of March.

And since we have a lack of 56 pieces here, we should enter 60.

I’ll just ask for two more just to have some slack.

So, now in the manufacturing, in this scenario, I will ask the manufacturing department to provide 62 instead of four.

And if that’s possible, I should be lucky.

So, now, of course, this doesn’t automatically reassign my sales order.

I could have many sales orders that wasn’t assigned, but now the quantity should fit.

And with a report, assigned quantity, it’s possible for me to reassign.

This report is more detailed, explained in other videos, but I would like to delete all the soft assignments within whatever period, and then to reassign, and I’m only calculating for this one item on that specific location, because this is all I need.

I just changed my supply, and now it should reassign for everything.

And as you can see here, everything is now assigned. I’m happy.

And if we look at the graphical profile again, now without the assigned quantity, it shouldn’t go below zero.

So, in this scenario, I have two as expected, the two extra I planned.

So, now I’m happy, and all the sales order reassigned in order of appearance.