When you use the Assign Quantity, it’s possible to include supply orders, which would be normal for most of our customer, at least, to do.

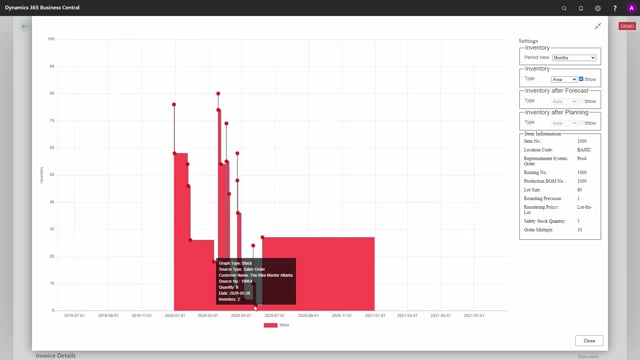

So, if, for instance, on this item, if we look at the graphical profile, which is a free app, not including assigned quantity, we could see how the complete profile is for this item.

There will be a minimum of two, and an end inventory of 27 in this scenario.

But we can also see that we have included firm plan production orders, firm plan production orders.

It could also have been purchase orders, inbound transfer orders, or assembly orders.

So, all the supply we have selected to include, and of course, we need for those supplies to arrive on time to make everything being perfect.

Now let’s take a scenario where one of those supplies are delayed.

For instance, a firm plan production order 145 here, and a quantity of 50 might be delayed because some components are delayed.

It could also have been a purchase order that is delayed in quantity or time.

So, if we enter the scenario, the firm plan production order, and we try to delay the order because this is what might happen for some reason, we will change it from 24th of April till 24th of June, because whatever reason, like this.

And now we need to figure out what will happen to our sales order, like this.

And if we look at the inventory profile now, before reassigning the sales order lines, we could look at the inventory profile, and we could see now that we have a lot of issue here on all those sales order.

With other apps, it’s possible to calculate to move those sales order, but with this assigned quantity app, it’s at least possible to remove this assignment here.

Of course, if we look at the inventory profile, including assigned quantity, it would now be wrong because we have just moved a supply and done nothing else.

So, therefore, we have actually assigned quantity on sales order lines, which is not correct.

Therefore, we could use the report.

And we’re aware of customers that is actually using this report as a daily or nightly batch job to reassign this again and again.

You can determine that yourself.

So, now we run on only one item, location filter basic, just to delete all the soft assignments and reassign them.

And it will calculate in the order of sales order, taking the first entered sales order first, et cetera.

Now if we look at the graphical profile now, and here, and we include assigned quantity, hopefully the assigned quantity will not get below zero, but we can also see the inventory is now seven to five instead of 27, meaning there will be quite a lot of sales order that wasn’t assigned in this scenario.

So, there will be many sales order that didn’t get any quantity.

And again, if we look at the inventory profile like this, not including assigned quantity, we can find the sales order that didn’t get any quantity here and figure out what to do with those.

So, it’s possible to handle delayed or quantity changes of supplies.