Assigned quantity relates to demand lines, and if you use the production module, a production order will have component lines and components are demands.

This means when you enter a quantity like this on a production order and you refresh the production order, it’s possible to automatically assign to the component line or you can do it all manually.

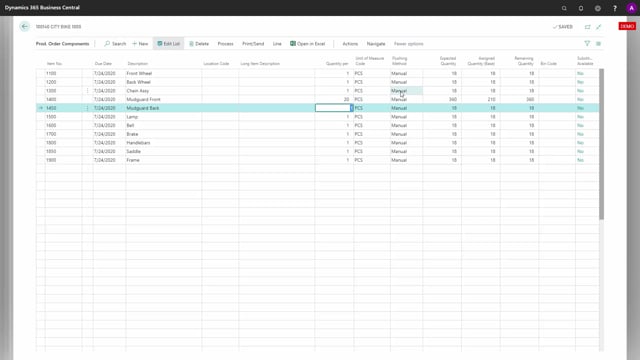

So, on my production order line, if I enter the components, and in this scenario, I just made 18 quantity, expected quantity of 18, and I can see the assigned quantity base is filled in automatically and it relates to my remaining quantity.

If I’m changing the quantity on one of the lines, let’s for some reason say that I need 20 per piece for this one, the expected quantity will be 360.

And in this case, it only assigned 210, which is the available quantity to assign.

This assignment is done automatically because I have checkmarked the setup to do it automatically, but it’s also possible to just manually enter the quantity like you can do on sales order lines.

And the setup is made in the item availability general setup.

In here, in the Assign Quantity, on the Assign Quantity tab, in the section down here, you can auto-assign production order lines and this will make it assign on release production orders only.

So, it only accounts for release production orders to be assigned automatically.

There’s also a function on the release production order and the firm plan production order where you can assign manually to this one production order.