Playlists Manage

Log in to create a playlist or see your existing playlists.

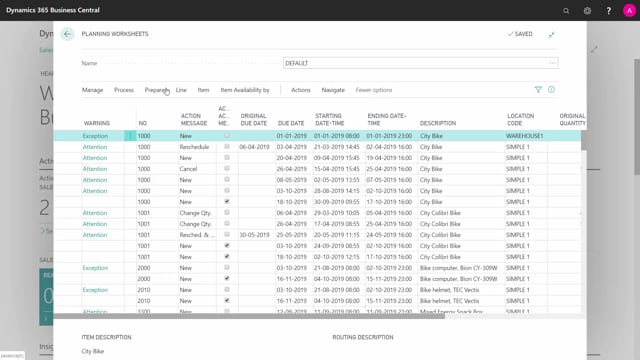

Log inHow to define fields when running a MRP batch job in the planning worksheet in Business Central?

I will give you a short introduction to how to define the fields and settings when you run an MRP batch job in a planning worksheet.

This is what happens in the video

Those are the same information in the requisition worksheet, except for a few things that you could only do with the planning worksheet.

So when I’m calculating the regenerative plan in here, I will have some options.

First of all, I can select whether to calculate MPS or MRP meaning the master production schedule, the material requirement planning. And in a separate video, I will go into the difference between those two.

Then I select my starting date meaning everything that is before my starting date when I do the planning will be in a frozen zone and not changed.

So if I don’t want to change any orders within the next two weeks because I already planned them in details, I will just add a starting dates two weeks from now, and of course, the ending dates determines how far ahead I would like to plan and I need to take into account all my purchase orders in the future, I need to plan for. So I need to plan far enough to get all my demands into the journal and be able to bring them down.

If I select the stop and show first error, the planning will stop if there’s an error, if a bill of material is not certified, if an item is blocked or whatever, and if I don’t select it, it will just run through and provide a list of errors afterwards.

And of course, I need to replan after fixing that list because the demands won’t be breaking correctly down.

If I use forecast, I can hear select the forecast I’m using, and if I only want to use forecast from a date in the future, I can select that. By default, it will always be from today and forward or the last forecast period months I’m in and forward, but I could say, I will not include forecast for the next month, for instance, and I only look before or after that. I could do that here.

Respect planning parameters for exception warning means if you do not checkmark this and you will have safety stock breach or other stuff that make warnings in the journal, they will not respect the order modifiers on the item card if you don’t checkmark this, so you have a minimum quantity, lot size, a reorder quantity, Etc, they will not be respected if you don’t checkmark this.

So it’s a matter of what you want the system to do for you and then you can filter on all the fields from the items, and location filters, Etc to determine which supplies to take into account when you do with the planning. This is how you set it up.