Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inHow does a Lot for Lot reordering policy suggest new orders in Business Central?

Let’s take a look at the reordering policy lot for lot to see how that is suggesting new orders.

This is what happens in the video

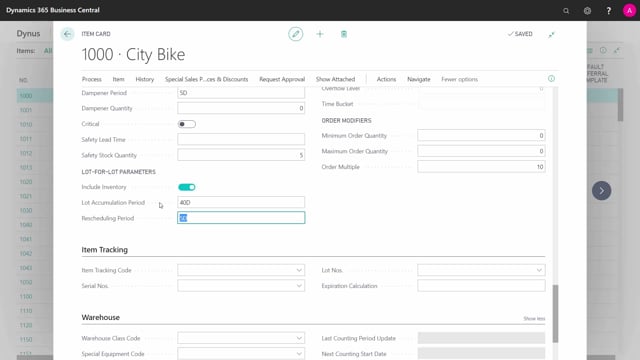

Entering my item card, I can see in the planning section that we can define a reordering policy and if the reordering policy like this is lot for lot, I need to define, first of all, will I include inventory and then a lot accumulation period.

So for instance, if I’m changing the lot accumulation period to 40 days, it will bundle demands into all those within a period of 40 days. Let’s see how it looks if we draw it.

So the lot for lot, we have all the demands. Those might be many demands and in different sizes, so the size of the green arrows will represent the auto-size. Maybe we already have an inventory level at the present date. We might have a safety stock, and we have triggering on all those different actions.

When a demand is up, it would be triggered in this way. So the inventory level in the frozen zone and the frozen zone is a period before starting date. So don’t change all those before starting date if we use the frozen zone.

Then there’s the inventory level, the expected inventory level here being lowered by the demands, the arrows here. So every time there is a sales order or whatever demand, it will lower the inventory.

And if we reach the safety stock level and get below the safety stock level, it will, of course, create a new order, but basically lot for lot should only go into the safety stock level and do nothing. That means it will trigger by demand up here in this example and it will look 40 days ahead because my lot accumulation period is set to 40 days.

This means it will accumulate those four orders within that period and making one production order if it’s a produced item, of course, with the lead time here and an order size of 20 if the sum of those 4 here were 20.

So the next time will be over here whether it’s a demand and it will look again 40 days ahead making this example an order size of 26 and the lead time will be longer if it’s a production item. So this is good for a seasonal items because as you can see in the end, the orders grow bigger because the demand is getting more tight.

So the order sizes will depend on the demand in the lot accumulation period and this is how lot for lot is working.