Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inHow to perform low-level planning with master data planner in Business Central?

Let me give you an example of how a master data planner could perform low-level planning in the planning worksheet and then handed over to the master purchase planner to do purchase planning in the master planning period.

This is what happens in the video

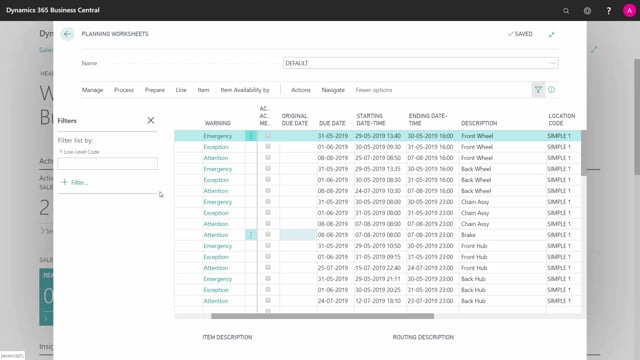

First of all, we’ll go into the planning worksheet and in here, I would like to calculate a plan and what I’m doing now is calculating, for instance, from 1st of June till September, I will calculate only production orders and in this scenario, I will calculate on all low-level codes and there’s a reason for that. I’ll get back to that in the end of the video.

Normally, you could also do this per low-level code and I’m going to do it again and again and again and I’ll show you why and explain to you why. So this are the lines in here and maybe if we scroll right, you could see whatever came up. So, for instance, the front wheel and back wheel hold codes for 140 pieces, Etc.

What I want to do now is to change my suggested orders on the top level. This means I will filter on my low-level code.

And I will filter on low-level code 0 which is the top-level that I’m handling first and maybe I want to change the orders for some reason. I want the first one to be a 50 because the marketing system that they make a big campaign likewise on the next one and maybe even the third one. So for whatever reason, I’m doing changes on the low-level code production orders.

What I want to do next is to check the capacity.

I will do separate videos on that, but actually I should check now the capacity in those periods for those order meaning the capacity planning, what does it look like? Is it possible to make three orders like this? And that’s actually why I also need the other lines in the journal on the low level through because if I’m looking at capacity influence, I would like to do the planning now, but I’ll get back to that in other videos, but that’s the reason for having all the lines here.

Now. I have changed the lines. I might have looked into the capacities and maybe even showed the column here planning flexibility to lock the line if I want to do that. That’s up to you if you want to use planning flex and locking lines and then I can carry out those three lines, carry out action messages.

I would like to make firm planned production orders because the plan I would like to use for the long-term planning for the purchases and the released, I would like to use for the detailed planning for the diesel planning people.

I remove my filter here on low-level code.

So now see the rest of the lines and I’ll plan again because I know the quantities in those lines are wrong because I changed the level 0 lines.

So I’ll just plan again, but now I will filter on my low-level code.

And I will plan on level 1 and further on, and again, I’ll take all the levels from one and down to be able to perform my capacity planning here and I can see if I scroll right now that all my quantities changed before they were 140.

Now, they’re something else because of my changes on level 0.

Now, I filter on level one.

I handle all those lines. I might do new changes, move dates, look at capacities, locking the lines if I want to, and doing everything that I think makes sense as of what I knew now, and then again carry out, and I will carry out to firm planned orders. And this way I’ll just continue deleting my low-level code, prepare, calculate.

Now, I’m on low level code to and further still only production orders because I’m the production master planner guy. I have now.

And I can filter here on level two, and I can see now, these are the remaining lines. So I have no items or no demands on Level 3 in this journal of production orders.

So again, I can handle, look into capacities, etc, etc, etc, and I will carry out.

So this is now all my firm planned orders in that period being planned from the top low level and down in a way that I still think makes sense.

The output of that would be that I have now a list of firm planned orders. I’m able to draw out capacity needs on all the dates I would expect to be, that would be right and I can hand out to the purchasers, they can now do their planning on all purchase items simply by -oops by going into the plan.

So the need to remove the low-level code, of course, change the replenishment system to purchase order and run the plan. I’ll explain in other videos how the purchaser in the master planning area can do his planning, but basically this is all the suggested purchase orders that he would need.

Now, the reason that I was running the full plan was actually to be able to do the capacity overview per low-level code and if I want to view the nice capacity overview on level 0, also need to have some kind of suggesting for the low-level demand or the low-level capacities or otherwise if they use the same capacities, it will make a wrong picture for me. So that’s why.