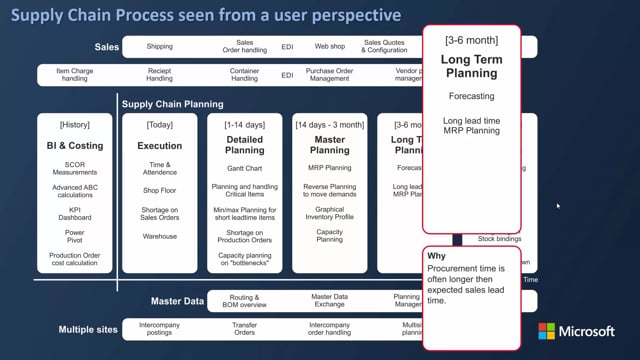

How to use the MRP Planning with Forecast to break down the Long Term requirements for Purchase Items in Business Central?

As a long term planner, typically being a purchaser, I would like to use the MRP batch job to break down my requirement from sales forecast. That is a long term. I will assume that I have some sales forecast here, and I can now enter my planning worksheet.

This is what happens in the video

And in the planning worksheet, I need to have a starting date that I have figured out already being on the other side of me and I’ll show you with a small example why I need that starting date to be precisely.

So as of today, maybe it’s in the middle of March, for instance, and if I’m planning now, let’s say first of January till December 31, and today it’s, for instance, March in 2019 this example, and I only plan production orders.

So this example, I can see I have a lot of change quantities, rescheduling, Etc, because I’m handling existing order because I have a starting date that is interfering in my existing orders. I’ll just delete this and try again and show you how to do it correctly.

So what I should have done instead, I should calculate my plan with the MRP but sitting a starting date on 1st of June because that’s the other side of my firm planned and released production orders. In this example, I will only plan production order to show how it works because I’m going to break down the hierarchy. So I’ll great demands on my production order used for my purchase supply. So in this way, I have now a lot of orders and they’re all action-type new because they’re in the long term period, and as you can see on the quantities of orders, it’s not that big because I didn’t plan my purchase orders.

Here I could change the specific order if I wanted to, to navigate into the -to the components and maybe change some of that if I want to. So this is my base for doing my long-term purchase planning.

So what I can do now, I could calculate my plan again.

And plan in the same period for purchase items. I could have done it in one go if I wanted to and this will now calculate purchase orders in the long term, but real life, I like to carry out action messages for those lines to planned production orders instead and then do the purchase planning. I will show you that in another video.