How to work with MRP Planning when calculated in Low-Level Code order in Business Central?

When you run MRP planning, the planning is carried out in low-level code order or reverse low-level code order to make sure to get all the depending demand calculated first. Let’s see how it looks in the system and then I’ll show you in a small drawing how it is.

This is what happens in the video

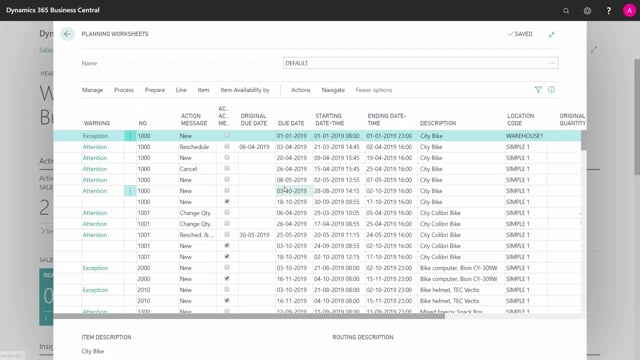

So planning worksheet.

I would like to calculate my plan and you have to be aware of the small message box while we plan and I will plan for everything so you can see now low-level code and it says zero and then I plan some items, now it says one and I plan other items but those item are a mixture of production item, purchase item, transfer items, etc. Now with some low-level codes 2, 3, etc.

So those low-level codes are calculated automatically when you certify your bill of material if you have set and you should in your manufacturing set up.

Let me just show you here the checkmark called dynamic low-level code. The only reason for not setting this checkmark is if you have we complex bill of materials, it might take a long time to certify your bill of material each time.

So, what actually happens is this.

So, if this is your hierarchy of production items and purchase items, I have just left out the transfer item in this scenario.

What will happen is that the MRP planning will plan first on low-level code zero. In this scenario, both production items, then low-level code one, meaning one production item, two purchase items, then low-level code two, etc. So, plans per low-level code, so you cannot speak of one item as being a lower-level item because it’s purchase or a higher level item because it’s a production item. It’s depending on how it fits in the hierarchy. And of course, as you can see in this drawing you need to plan everything in the highest low-level code first and then down the hierarchy.