How to do Capacity Planning in Business Central?

If you want to do a nice capacity planning with your Business Central Solution, you might want to take some other apps into account as well. But in this video, I will show you shortly how it works with the standard functionality. So the data set for doing good capacity planning is actually here.

This is what happens in the video

We do have some assumptions though that you need to take into account. First of all, let’s look quickly at the capacity load report meaning the sorry the work center load report meaning the report that shows how much our capacities are loaded. So if I have a date here, for instance, first of June 8 weeks and I view this report, I get an overview of all my capacities per week that I set in the capacities work center.

You can see the capacity.

What’s actually there. You can see the needed capacity. What is actually booked, and you can see what is available in the period. So on the first line is booked for 9.4% in that period.

So if you scroll down, for instance, you can see that in the period from 13th till 19th of July, our machine department is actually booked 219%. This means we’re booked with infinite capacity, meaning you can do more than a 100% capacities if you have in place many production orders at the same time, the capacity percentage or the capacity load will just increase.

So where do those numbers come from? Let’s take a look here.

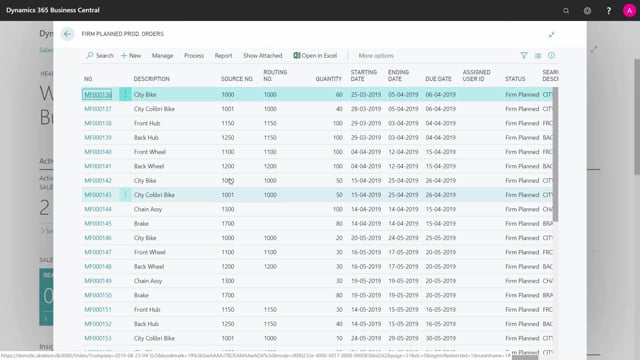

When you create a production order, even if it’s planned, firm planned or released. In here, I’ll just want to filter on my starting date looking downwards here and I have my production order here in that period we know we have some allocations. This is a production order.

We have created it and when you create it, it will automatically make routing lines related to that production order line. So this is my production order routing lines for each of those lines, and can see the different works on those here for each of those lines. It would have created allocated capacity entries.

So these are the entries that actually sums up and is used in the report. You can see here that we have more than one shift and you can see the allocated time in minutes in this example per shift. So this capacity entries are calculated in the works and the load report and those entries you can also use to calculate using many other tools to see your capacity set up. So this is how capacity planning can work.

You can see the dates here if you are moving the production order. So if you see here, I would like it to start instead on another date, a week later maybe.

It will move the production order date recalculating the production order automatically, meaning if you go into your routing, your allocated capacities and you can see here the dates have been moved. So this is a way of moving the production order.

So what you really need if you want to do capacity planning is an overview tool to see when your work centers are overloaded and then you can move them either manually or Gantt Charts, etc.