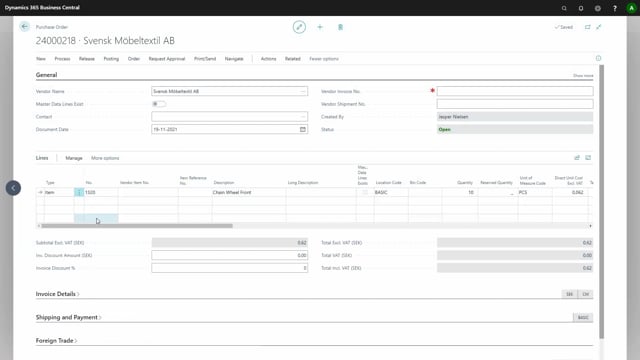

As a part of the Purchase Order Management, we have added some extra date fields on the purchase order line. As you can see here, we do have the vendor transport method, we have the transport time, and we had a lead time calculation, which is a calculation of several date formats. So let’s try to explain it.

So let’s see all the dates on the purchase order lines. First upon, we look on the standard date fields. First we do have the order date, we have the planned receipt date, and that’s the date when we expect the goods, the items, to land out on the ramp at our porch, so we are ready to unpack them. That’s the planned receipt date. Between the order date and the planned receipt date is the lead time calculation. The lead time calculation is the lead time, the vendor lead time, set up on the vendor card. So that’s the time from we order to we expect to have the things ready on the ramp.

Then we have the expected receipt date. That’s when the items are available. So that will be the date where we are ready to pick and ship off the items to our customers. The time between the planned receipt date, which is on the ramp, and the expected receipt date, we do call that the inbound warehouse handling time and the safety lead time. So the inbound warehouse handling time is what we need to receive and put on stock.

The safety lead time is a buffer, and normally in all systems that is set up to a one day buffer, and that’s overall. So what we added in the Purchase Order Management is that we added a vendor lead time. The vendor lead time is the time the vendor needs to produce or purchase or whatever the vendor does, but actually the time it takes the vendor to internally handle the item. So that will be the date from the order date until they are ready to ship them from the vendor. We call that the expected shipment date. Then we do have the transport time. And together the vendor lead time, the internal time at the vendor, and the transport time will make the overall lead time calculation. So still the date from the order date till the planned receipt date. And the transport time that we use are based on the transport method, which are set up on each vendor. So this means in this case that the expected receipt date, the 1st of December, is the date that we can use the goods.

Before that we do have a planned receipt date, that’s where the items are on the ramp, and that’s five or six days before, because that’s the inbound warehouse handling time and the safety time. The lead time calculation says that it takes 21 days and 6 weeks, and that’s because the transport time is in this case the 6 weeks, and the internal vendor lead time is 21 days. So the lead time calculation, which by the way is a standard field we use otherwise, is now the vendor internal handling time and the transport time. So the expected shipment date, that will be the planned receipt date minus the transport time, which is 6 weeks, which means that the order date should be at least 21 days before the 14th of October.

If I change the transport time on the vendor and say, let’s go by air, and I’ve calculated from my expected receipt date, so when the things should be ready on the ramp, and this means that my planned receipt date on the ramp, so I calculated from the expected receipt date the day when I can sell my goods. And that means that the planned receipt date is only three days earlier, and that’s because the inbounds warehouse handling time is only two days when I come with air and the one day buffer. The lead time calculation is three days plus the 21 days, because the 21 days is still the internal lead time for the vendor at their factory, and three days is my transport time, which means that I expect the vendor to have the shipment ready from their factory on the 25th of November. So by using dates in this format, you are more able to control how long time you use in the whole lead time on transportation.