How to determine quantities for safety stock, reorder pont and order quantity in Business Central?

We often ask how to determine quantities for safety stock, reorder point, or reorder quantity that you define on the item card and I’ll just give you some small advice on that one, at least what I used to tell my clients.

This is what happens in the video

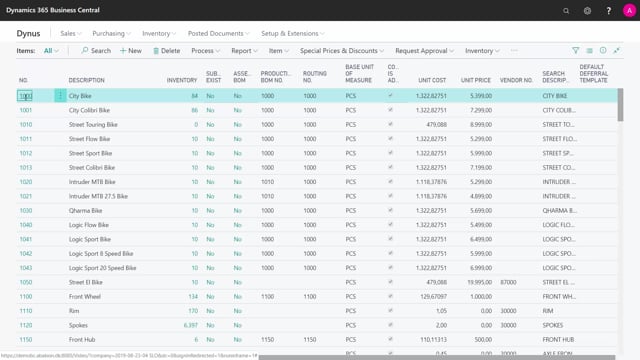

So on the planning tab on the item card, we have the field safety stock quantity here. And if you plan with fixed reorder quantity or maximum quantity, you also need to enter the reorder point and the reorder quantity.

Basically, you just have to understand the item like if it was an item in your kitchen or ask your purchasers what they actually do. So when I want to handle this item, how do I actually wanted to react in the real-life? So the safety stock quantity will be interpreted by the system as a zero quantity.

So this is the zero level meaning, I always want to have five on my inventory.

So when it’s planning, it will assume we should always have at least five. So we have a safety breach because of some upcoming demands that we haven’t seen.

It will plan backwards and make the planning lines more urgent. So this is like a secure inventory for us and you just have to ask yourself, how much wood would like always to have on inventory for the specific item? And it relates of course to the service level you would like to have and so the inventory binding meaning how expensive is the item. So the safety stock quantity normally relates to the service level. The highest safety stock quantity, the more you’re able to provide the items for your customers.

So you need to fill in the reorder point and the reorder quantity as well and the normal way to do this would be to think of the reorder quantity. So, how many would I normally buy in one go from the specific vendor or how many would I produce if it’s a manufacturer item or if it’s flour for my kitchen, how many kilos do I use to buy at a time?

And that’s often more easy to answer than the reorder point because if this is flour in my kitchen, I will enter 2-kilo flour and then afterwards I’ll ask myself, how long does this two kilos actually last. How long would I expect it to last? And that also determines my reorder point meaning how long does it take to replenish the flour? It’s like one or two days and how long does it take for me to use the flower? And that’s the way I calculate the reorder point.

So think about the item on the shelf and the demand will take away the items from the shelf and when it reaches a certain point, we need to order the item either produce it or purchase it depending on the replenishment system.

So it’s the lead time that determines the reorder point and the reorder quantity determines how often you want to replenish it and in how big quantities, and, of course, the higher quantities, the more you get on inventory, but the fewer orders you have to do.

So, there’s lots of theory on how to calculate the reorder point and you can do this with the double ABC analysis or multiple ABC analysis, Wilson’s formula, Etc, and we’ll do videos on those as well if you want to really dig into how it’s done, but a normal good advice would be to ask yourself, what would I normally do with this item? Starting with the safety stock then the reorder quantity and then, in the end, the reorder point.