How to set up reordering policies on items in Business Central?

Let me introduce you to how to set up reorder policies on items or stock-keeping units, but I will not in this video go into details about when to select or what, I will show that in other videos.

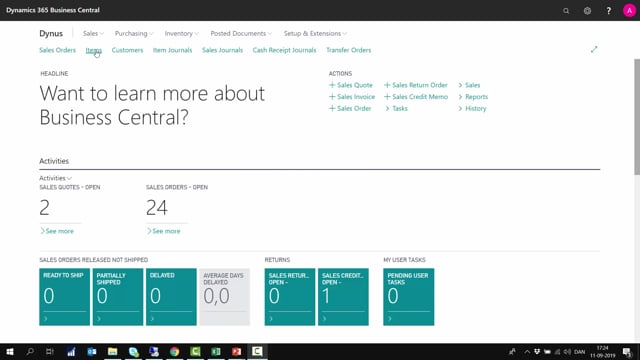

This is what happens in the video

On the item card, if I scroll into my planning tab.

Meaning, how would I like to plan this item, meaning which quantities and which due dates would I like to plan. I can select my reorder policy in the top. So I can select fixed reorder quantity, maximum quantity, order, or lot-for-lot and I’ll just briefly explain the difference of those four. So if you select fixed reorder quantity, you can add basically a reorder point and a reorder quantity, and you also want to use often these safety stock quantity down here and it’s part of the general fields here because it also applies to lot-for-lot planning.

Adding reorder point and reorder quantity will be normal min-max calculation. So when you’re planning we’ll assume that an item hits the reorder point. It will make an order of the reorder quantity.

In other videos, we will explain more in detail how that works.

Using maximum quantity is all the same fields except instead of reorder quantity, we have maximum inventory level and this is meant to fill up the inventory to the brim that you define here. So you have an inventory maximum and when you plan, the system will try to fill up the inventory as much as possible.

Not many customers use this because in this theory, it doesn’t always make sense because it’s a planning looking ahead. So we might exceed the maximum inventory with this kind of planning and then how can we stop the item into there.

The next one is the order. Reordering policy order. When we select that one, we will plan per each demand. So every time there’s a demand, it will create an order on the specific item. So it’s a one-to-one, and it’s the simple one to understand basically. On the last one, the lot for not will add demands together. So it will look in the lot accumulation period and defined, look into all the demands in that period and add them together and pile them into one order and it could take into the account the safety stock and inventory if you select that. We’ll go more into details about those different ways of planning in other more specific videos.

And as I said in the beginning, if you go to the stock keeping unit card, you can overwrite this menu. You can define per item, per location more specific planning parameters.

So if you take the item thousand on location symbol one you defined here. How would you like to plan that more specifically?