Which fields relates to replenishment system production in Business Central?

Let’s take a look at the fields that relates to replenishment system production on the item card.

This is what happens in the video

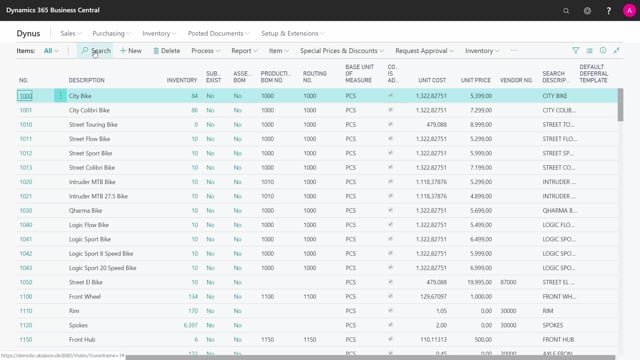

I will go on my item thousand as an example to the area of replenishment down here. So if it’s a production order in the replenishment system, this is the modules, the fields below here on my production site, meaning my manufacturing policy, Etc. Let’s run through those. First of all, manufacturing policy could be made to stock, or made to order. You have to be aware this has nothing to do with the planning on the planning area further down. This has to do only with the fact if you want to bundle production orders, several production order lines into one production order when you create them or you want to make them separately to stock production order per production order. In my experience, 99% of our customers use mixture stock as manufacturing policy, so I wouldn’t get too much into that if I were you. So the routing number is selected from a list of routings that you set up and it describes the operation and the work centers or machine centers you need to perform the operation for doing this item. So it’s a list of steps you need to do like in the kitchen, it’s your recipe when you’re cooking.

Whereas the production numbers for the kitchen metaphor is the thing to need to use, your ingredients.

So the production BOM is also selected from a list that you maintain where you add all the components and the quantity pairs that you need to add to this item to build it.

Rounding precision is used if you want when you create production orders to round it when it’s planning. You should round into whole figures or whatever.

The flushing method is used when you create a production order if the components you are drawing into the production order should be flushed manually in a consumption journal or if you want it to be flushed automatically when you plan your production order meaning forward or when you finish your production order meaning backwards. So you’re flushing determines whether to flush components automatically or manually.

Overhead rate and scrap percent is used to calculate the standard cost for the item when you roll up the standard cost and it has to do if this item when you produce it, would you normally have extra cost you would like to add to the item, it directly here. So for instance of overhead rate of two Euros could be depending on cost you have that you don’t want to add into your routing but you want to add it manually here on the production order and the same with scrap percentage.

You can set up here a normal percentage that your scrap when you produce it in the production order and that will affect the standard cost making the item more expensive. The lot size is used only for calculating the cost price. So when you determine a lot size of 80 in this example and you have set up time in your routing, this is used to calculate your standard cost based on the setup time on the routing.

And again on the stock keeping unit card, if you go to this card; stock-keeping unit cap in here and you have locations on that item, you can also change some of the replenishment parameters, but not all of them. So you can change here manufacturing policy, flushing method, components at location, and lot sizes, and note here, there’s a new field called components at location.

That means if you plan on this specific location on this SKU card, you can draw items and consumption journals automatically from other locations. So when you refresh the production order, it will suggest other locations to draw the components from.

So these are the fields you can set up for replenishment system production order.