Which fields relates to the replenishment system assembly in Business Central?

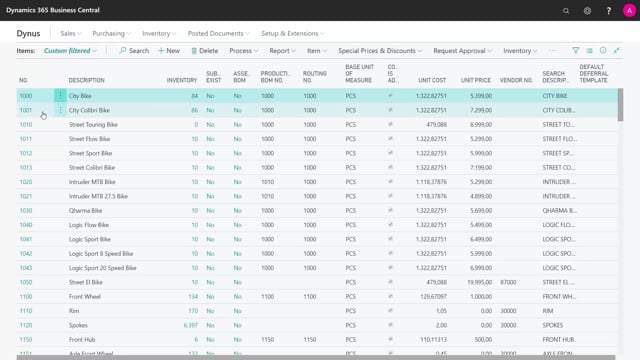

Let’s take a look at some of the fields you need to set up if you use replenishment system assembly, and I do have two items here in my demo data, my mixed energy snack box for instance.

This is what happens in the video

That’s an assembly item, and also if I go to my replenishment tab here, I have selected replenishment system to be assembly meaning when I don’t want to use production order but I will draw from a bill of material items and create the top-level item. This one is set up as assemble to stock and it has an assembly BOM. I can click here the assembly BOM and open it and see the two parts that it’s made of. I could also have found it in the menu up here or just search for it.

Here on my page, I have the assembly BOM on the item and here I can, of course, change the item and define quantity per, and I could also have selected this set of items to use resources that looks into my standard job resource table. So I can add hourly cost to the items. Well, that would be calculated into the standard cost.

The fact that it’s assemble to stock means that I will create assembly orders when planning and we’ll have to open the assembly order and post consumption. And when I post the consumption, I also put item on inventory.

Whereas if I have chosen assemble to order instead, it will automatically create assembly orders when I enter the quantity on a sales order line, that means if I’ve entered this item number on a sales order line when I enter the quantity, it will create an assembly order below on the background and when I post my sales order, it automatically draws the components and puts on stock the top-level item, meaning this item, and post the item to the customer.

So the assemble to order is a way that you can actually pick underlying components automatically from a sales order. those information are, of course, also available on stock-keeping units.

So if you are using stock-keeping units, let’s see if we have one for this item.

Yep. I have one here on location simple one and again in my replenishment tab, I could define this. It’s also an assembly order on this location. If yes, I could change here the assemble to stock policy, but I cannot change the bill of material for this specific location. That’s also only possible to change on the item card. So this are the fields that relates to assembling.