How to set up demand forecasting for MRP planning in Business Central?

A demand forecast is created to make and demand for the MRP planning, that is used in the requisition worksheet or the planning worksheet, so when calculating the demands and suggesting orders for purchase and production and transfer, the demand forecast will create a fictive demand, if you don’t have sales orders for that period

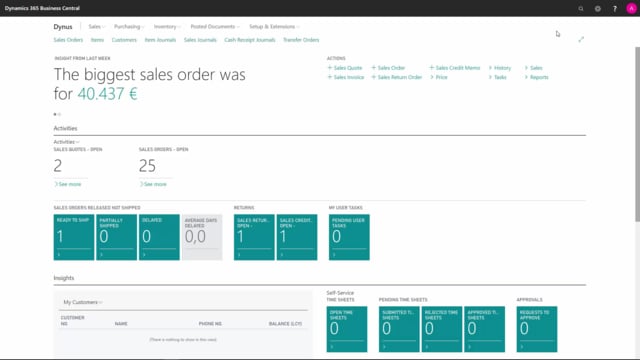

This is what happens in the video

Normally demand forecasts will be created, if your lead time on the outbound side and the sales side is required to be much smaller, than the lead time on the inbound side, so if you have a long purchase lead time on a small sales lead time, you can create sales forecast or demand forecasts to help with that.

So let’s see how it works you can define different demand forecasts, some people doing it per year some doing it rolling, we suggest normally to do a rolling demand forecast, but in this scenario is per year, and you define what period would you like to work with forecast in, be aware to use the same period all the time.

So normally we suggest month for our customers, how we experienced that our customers is mostly using month, so I can see here my forecast on, for instance my city bike is 90 pieces in May, and if I change that to 92 pieces, what it actually does is, it’s creating a new entry and I can drill down into it and see here, that on this date somebody created a new entry with two pieces, so it’s actually locking the changes when you change the forecast entries, so that’s very nice.

You can forecast on sales items or component items, meaning if you change the view to view component item, so that’s the demand coming from a production order component line, you could also here forecast maybe 12 as a component item, meaning if you’re viewing both of them, we can see a forecast of 104 on this city bike, and of course again if we view only the sales side, we just see the 90 pieces.

So, the forecast is written down by sales orders, the sales forecast amount and by production order component lines, the component amount, therefore it serves as a demand for component lines and sales line.

And you have to be aware that the forecast is working in a specific period, so the forecast for May, will only write down or being written down by the demands in May.

So they will always display 104 here in the view for both of them, meaning 90 from sales forecast, and whatever from component forecast, but when it calculates the MRP journal, in the period of May, it will see what do we actually have of sales orders and quantities sold, and take them out of the amount, so if we have sold a half open sales order with a hundred pieces in May, the forecast effect will be only four.

We have other videos on planning, to explain more detailed, how that works.

Be aware that you cannot change the forecast, when you have forecast type both, because you need to tell the system, if it’s forecast if it’s based on a sales item or component.

So therefore, if I change my quantities now, I will just get a validation result.

So, if I want to change the component, the forecast I need to select one of them.

Now if I want to view by another period, maybe by week, I can see that the forecast is actually on week 18, but maybe the first date of week 18, Monday in week 18 is not on the 1st of May, so if I’m changing my forecast here to, for instance a hundred pieces, it tells me that we have some conflict of the forecast entries and suggests to move it, till the start of the period, because if you don’t do this, you’ll have some problem.

Let me show you here, I will say a 100, and if I view it per day, I can see now the forecast is on the 29th of April.

If I’ve said no to that, I will have quantity on the 29th of April and another quantity remaining on May, meaning my forecast period from April would only be, or for 29th of April would only be, two days.

So, we have to be aware of using, theoretically, the same period for all forecasts, that would be the best thing to do.

Normally if you use location, you would forecast per location, all of these forecast entries, that I have made here, is with no location code.

So here, I can see the location code is not filled in, meaning it will only create demand on location blank, so to speak, so the normal way would be – if I go back on my month view, to forecast per location, so maybe you have a main location you’re working on, or you should at least be forecasting per different location, because the MRP planning in both the requisition worksheet and planning worksheet, will run per location no matter what you do, so here if I’m forecasting 20 in May on that location, it will not display 20 and if I remove my location filter first of May, it will display 110, this means if I now add to my forecast here, I will get an error because in real life some of this entries are now with the location code, and some of them are not.

So now, it’s not possible to enter here without either saying location code blank, displaying the quantity on the blank location or location code sample 1 etc.

So be aware of how you enter this forecast.

All these parameters go into the MRP planning in the requisition worksheet, and the planning worksheet.