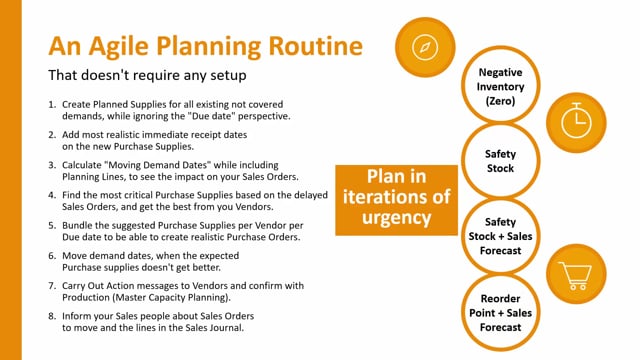

In this video, I will show you what we call an agile planning routine, which is a planning routine that doesn’t require any setup, or you could do the setup while you go along.

And it’s a routine that you can use again and again in different levels.

Let’s see how that works.

First of all, you should create plan supply for all your existing not covered demands while ignoring the due dates perspective.

And this is done to avoid all the changes, all the cancellations or reschedules, but only to figure out what do we need on the purchase side that we haven’t yet created supplies for, and therefore we ignore the due dates and plan with end date.

Second, you should add the most realistic immediate receipt dates on your new purchase supplies.

So, if you open the quick journal and look into the suggested supplies that you need to create, just figure out the immediate dates when you think it’s possible to get those purchase supplies.

Next, you will calculate the moving demand dates while including planning lines to see the impact on the sales order side.

So, with this functionality, on this process, you can see all the sales order that you need to push according to your supplies that you just created, and thereby take actions on that, but still on the planning line.

Next, you will find the most critical purchase supplies based on the delayed sales orders and then get the best from your vendors.

That is, take a discussion with your sales people and find out which purchase supply is most problematic to fulfill sales orders or which sales orders still need more than you can cope with, and then try to figure out the best possible solution on the purchase side.

And next, you will bundle the purchase supplies still in your planning journal, so, that instead of many different dates per vendor, you will bundle them per realistic due date.

So, you will make maybe several purchase orders per vendor, but not as many as you have different lines, and thereby you will bundle the purchase supplies in a way that makes sense in real life.

Then you calculate the move demands, again based on the new purchase supply date you made in the planning journal, and you can see now what the consequences will be after changing those purchase supplies.

After that, you will have a quick journal with all the suggestion lines that you actually want to make orders on, and you can carry out orders for your vendors that you suggested, and you need to confirm, of course, with your production, and if you’re a production company, this is the place where you should do the master capacity planning to figure out if you need to move due dates on the suggested production orders as well.

And if you do that, you will need to go back to number six and reschedule for the production orders up against the sales orders.

If you don’t use production orders, you can just leave it here.

And the last thing you need to do is, of course, to inform your sales people about the sales orders you have moved in the sales journal, and then they can take action from here and talk to the customers and move the sales orders.

This is one way of doing an agile planning, and you should do this in different iterations of urgency.

So, first of all, you could plan with true negative inventory, meaning the selection zero, so, where do we actually breach zero and need to perform on that.

And after you have no more lines left to calculate, you can plan against safety stock.

And then later on, after you have cleaned up that, you can plan against safety stock and maybe sales forecast if you’re using that, and then against reorder point.

So, you can do the iteration again and again and again with the same agile planning routine and being less and less urgent.