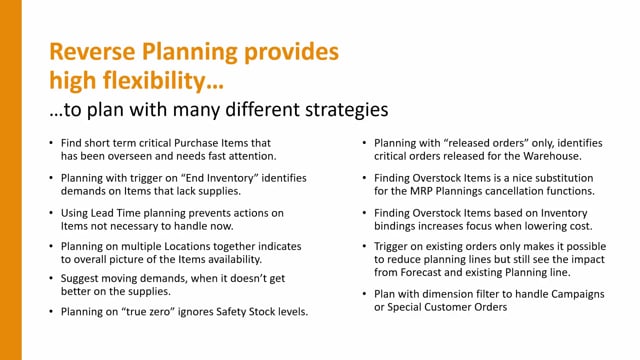

Reverse Planning provides high flexibility to plan in many different strategies.

And maybe those flexibility is the most important thing about this tool.

Let’s run through some of them.

First of all, it’s possible to find short-term critical purchase items that has been overseen and needs fast attention.

For instance, if you lack setting up replenishment system or reordering policies on the item.

Then it’s possible to plan with the trigger on end inventory, which identifies demands on item that lack supplies and that are actually critical.

It’s possible to use lead time planning to prevent actions on item not necessary to handle right now, meaning if an item has a short lead time, it’s not necessary to pop in the planning worksheet, whereas long lead time item needs to be planned far ahead.

So, it’s possible to distinguish between that.

It’s also possible to plan on multiple location together, which indicates an overall picture of an item’s availability, whereas the normal planning would only plan in one direction between locations.

You can suggest to move order demands when it doesn’t get better on the supply side, meaning when your purchase orders, for instance, doesn’t get better or your purchase planning, you can suggest how to move demands according to that.

Then you can plan on a true zero level, ignoring safety stock level, meaning you can plan either on true zero, safety stock, or reorder point, and it provides different flexibilities for the planner.

You can select to use release orders only, which plans more critical to the warehouse people.

So, if you want to, you can plan only on release purchase orders, release production orders, and release sales orders, or a mix of those to make it possible to see what is actually critical for things you want to release to the warehouse.

Then you can find overstock items, which is a nice substitution for the normal cancellation function in the MRP.

So, it’s possible to find item that runs overstock with too much stock according to a multiple of safety stock or reorder point or according to money bindings in the inventory.

And likewise, you can find the inventory bindings on the overstock item, and you can increase focus on that.

So, for instance, you can plan on the actual average inventory cost per item, and you can find the most expensive item on your inventory on the actual predicted value bindings on inventory.

You can select to trigger on existing orders only to make it possible to trigger on actual demands but to see quantities including planning lines and including forecasts.

So, it’s possible to include planning and forecast to see the effect on that, but only to trigger lines, show up lines that is triggered by true orders.

And finally, you can plan within dimension filters if you want to handle campaigns or special order requirements.

It’s possible to plan separately per dimension value.

So, this is some of all the features you can use for flexibility in the planning, and a good planning is actually a mix of all those different functions.