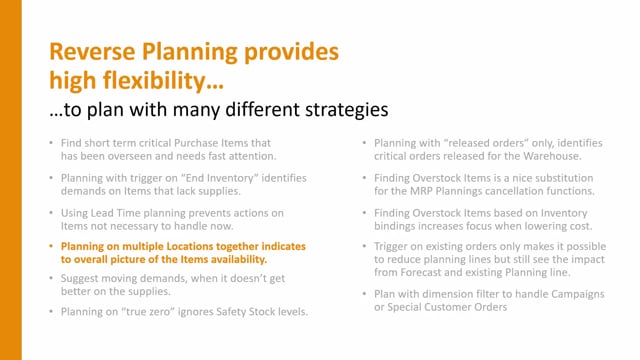

With Reverse Planning, it’s possible to plan on multiple locations together to indicate an overall picture of an item’s availability.

Let’s see how it works in Business Central.

From my Reverse Planning, I will calculate critical items to see if I have any issues in here, and I will calculate per location for each location, but I will plan on two location basic NVMS center.

So, when I’m planning this, it will select or calculate different lines for the two locations, and as you can see here, it calculates lines for basic location, NVMS center, and some of them in this scenario, it’s both items, item number 1320, they’re critical on both locations.

But take the top one here, 1255, it’s critical on location basic.

Let’s look at the graphical profile for that item.

So, if I view the profile, I can see that the item has a negative inventory of 38.

So, the normal planning will require me to plan this item and replenish this item.

If I’m looking at the same item on the location VMS center instead, if I’m looking at this location, I can see here that my inventory is positive with 150.

So, from an overall perspective, it’s not critical if it’s possible for me to move between locations.

Let’s look at the graphical profile on both locations at the same time.

So, it’s still just a graphical profile view, but I’m adding two locations together to see the combined inventory.

And this scenario, it has a positive in inventory.

This means if I was calculating my critical item instead of calculating per location, and be aware now the location code is filled in here, I will delete the lines like this and recalculate my critical items, but this time on the same two locations, but not calculating per location, meaning putting it all into one bucket while calculating.

So, now I will expect my item 1255 not to show up.

So, this is my items that are critical across locations, whereas the other item could be handled by moving stuff around.