One of the reasons that we created reverse planning in the first place was that the MRP planning was too complex for our clients to use. So we have many customers that would like to run MRP and learn how to use MRP. But in real life, the complexity of the suggestions was difficult to handle. So if this is an MRP journal, and I’m calculating for whatever items and intervals in here, it will suggest many lines for one item, often because it’s trying to moving orders, creating new orders and rescheduling orders. And you cannot take away those functionalities. So it’s not possible to say do not reschedule, for instance, on orders.

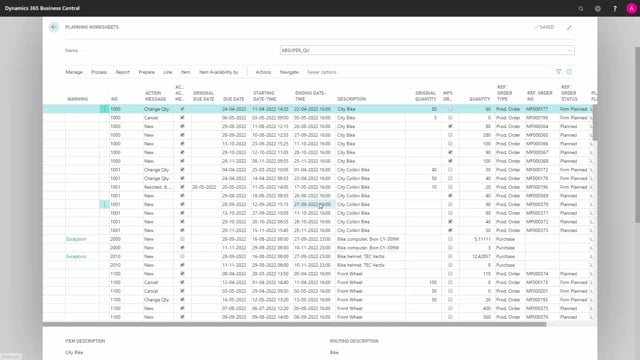

So the MRP is an actual intelligent planning way. It’s a mathematic algorithm that is very cool, and it does cool stuff, but it’s difficult to get on top of it and have everything calculated. This means that often in the MRP planning worksheet, you will see things like this on the same item number on the same location code, you have many quantity changes, new orders, etc. And you can handle this, of course, with the planning flexibility and other stuff like that in the standard Business Central. But in our experience, maybe one out of 20 customers who wants to actually run MRP planning, never get to it because it’s too difficult for them. Whereas in the reverse planning, we split some of the functions apart.

So we’re planning on critical items in one step, and moving item dates in another step. This means that except for understanding this request page, where all the logic lies, and all the flexibility lies, once you understood this request page in here, it’s much more simple for our customers to use this planning tool. And if I’m including forecast here, this is the same parameters I’m planning on as in the MRP planning worksheet. But as you can see here, it only creates one line per item. So on item number 1000, in the other worksheet, we have seven or eight lines.

Here it’s only one line, simply saying your inventory is 84, your end inventory is minus 344. And your lowest inventory, if you include forecast is minus 344. Whereas your lowest inventory, if you don’t include the forecast is actually positive, meaning if you run with, if you don’t sell anything on forecast, you still have a positive inventory. So it’s much simpler to overview and understand data and to create orders from in here.