Once you have had discussion with your vendors about the most critical delayed purchase supplies that you need to have, you can start to bundle your suggested purchase supplies per vendor per due date to be able to create realistic purchase orders, and you need to do that before doing the actual movement calculation.

But when you do it, you should be aware of the quantity and dates related to safety stock, order multiples, reorder points, forecast, etc.

Because if this is the first run of your Agile planning and you run it based on zero level, it might not have taken into account reorder points, etc.

And of course we don’t want to order too small quantity of the item.

If for instance we have a reorder point or reorder quantity that is higher than it’s suggested.

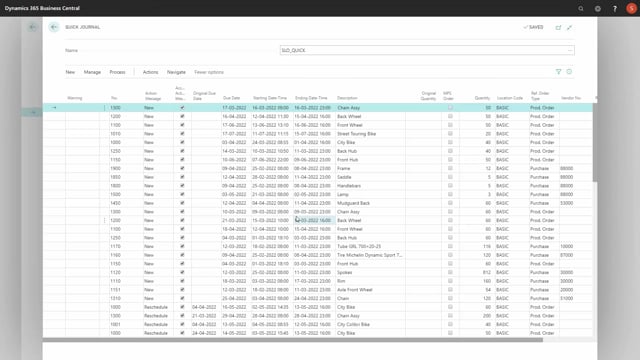

Let’s see in the journal.

So, if I have my quick journal like this, and it’s suggested a lot of orders, and I would like to filter on purchase orders, and I might want to filter per vendor, because these are different vendors.

Let me try to filter on the first one.

And if I look at the dates for this suggestion here, some of them are very close in April, one of them are three weeks later in May, and I might want to bundle the first one here to the same first date in April and the last one in May.

So, this way I’m bundling what I actually expect the vendor to supply, and I’ll do this per vendor, being able to calculate the movement and get a more exact calculation for that.

But while I’m doing this, I also need to take into account the quantity I’m ordering, because those very low quantity might not make sense.

Those are based on the zero calculation, meaning what I actually need to fulfill my demands.

I know the vendor has a higher quantity on stock, I might want to add, of course, the actual quantity I’m normally buying from the vendor.

Therefore, I’m updating my quantity with more logical quantities.

So, when I start calculating based on safety stock and reorder point later on, I already took that into account when handling those purchase lines.