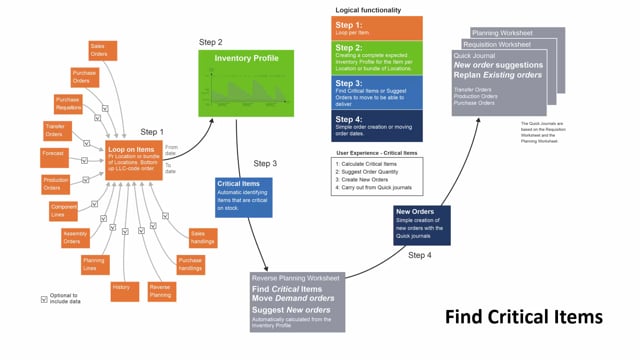

Let’s take a look at step three and four in the Reverse Planning when you calculate for critical items.

So, the first two step was to determining what to include in the graphical profile, So, it draws a profile for the item, and then it’s looking for critical item, which mean in step three it is identifying, do we get below safety stock, zero, or reorder point, depending on what you have determined in your request page.

And if you get below one of those criteria that you set, it creates a line in the Reverse Planning worksheet suggesting to create new orders.

You can handle that line, suggest order quantity, how many would you like to replenish, and then when you create orders in step four, it will actually move the lines into a journal we call a quick journal, which is basically a copy of the planning worksheet and requisition journal, So, it’s the same table, and from there you carry out actions like in the normal planning journals.

So, from the quick journal, you can create transfer orders, production orders, and purchase order very smooth from lines coming from the Reverse Planning worksheet.

This means the step that the user will experience looks like this.

First you calculate the critical items, then you suggest order quantity on the lines, and modify those, then you create new orders, which move the order lines into the quick journal, and then you carry out actions from the quick journals, which creates the different order types.

This is how you find critical items.