Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inUsing the classic MRP functionality in an ERP system that runs normal MRPs, I’ll do this on Optel item 3000, it’s almost impossible to get done.

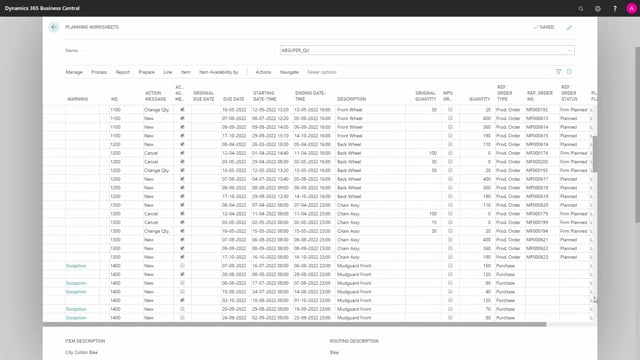

So, every time you calculate and adjust stuff, you carry out, you handle all the lines, existing demands that is moved just a little or new demands created, purchase orders that you postpone a little.

So, because you don’t have any flexibility in the request page, where you set up all the parameters you want to plan, the MRP planning will often create quite many lines that you need to handle and to look upon.

And in my experience with our customers, it’s almost impossible for them to get done with the MRP planning.

So, it will continue doing many lines that they have to look into.

In this scenario, I think it’s doing like 185 lines or something like that.

I’ve counted it.

Whereas in the Reverse Planning, it’s possible to set So, many different parameters in the request page.

So, when you’re looking for critical items, you can divide it up into many different steps.

For instance, saying to begin with, I will only look at the end inventory and true zero and whatever restrict parameters.

So, I would like to find all the most critical item first, then less critical, less critical, etc.

So, in this scenario, with the same item parameters, there’s only one line and not 185 lines.

When I’ve done with them, I can loosen up my criterias and take according to, for instance, safety stock, if that’s my next algorithm, maybe I would handle this line.

And then instead of looking at zero, I will look at safety stock item, which is the second critical and two more appears.

I could handle those, etc.

So, it’s easy to make processes where I get done with the planning and finish up what I’m doing.

And the more time I have, the more I could loosen up my parameters and getting more lines in the planning worksheet.

So, this is a very agile way of working with planning lines.