Playlists Manage

Log in to create a playlist or see your existing playlists.

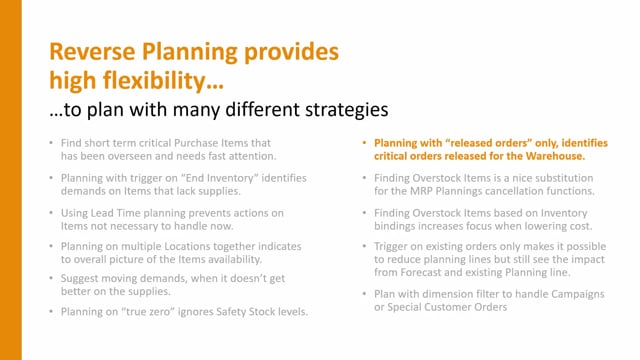

Log inWith Reverse Planning, it’s possible for me to distinguish between to plan with all orders or only released orders, and that makes sense according to warehouse and when to release different production orders, purchase orders, et cetera.

Let’s see how it works in Business Central.

So, while calculating critical items in Reverse Planning, it’s possible to me to select all sales orders, only sales orders, or released sales orders, likewise on the purchase orders, and likewise on production orders where I can select everything from planned to released.

First of all, I’ll just try to run all of it to see what happens when I plan with the criteria as for now.

If I’ve made the same plan and said I would only look at critical items maybe based on released production orders, meaning only released production orders and only released production components, the result would be quite different.

Actually, I only have three items to handle now.

Two of them are new.

Actually, all three are new because now I can’t fulfill my supplies on the sales because I lack production orders, but this also tells me that I have very few released production orders.

I could have done the same with purchase orders and sales orders.