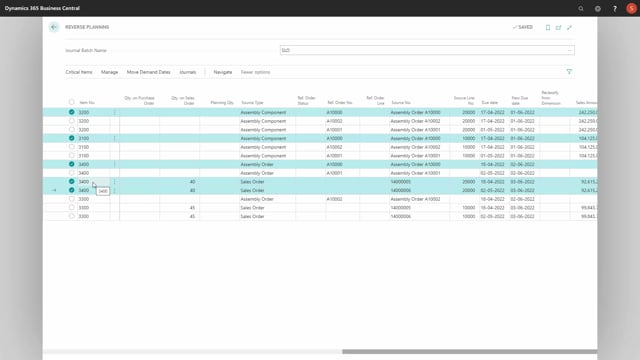

When you calculate for moving demand dates and you include assembly orders you need to understand the assembly order lines what they actually doing in this scenario I will calculate on my distribute location where I know that I have different assembly orders and I have some dates conflicts as we can see here it suggested a bunch of lines on components and it rolls up till my top level items that I’m selling and if I’m scrolling right I can see some of the lines are assembly component lines for instance this one on assembly order 10,000 there’s another component line on the same order and that’s the actual assembly order.

So, in this scenario those three are bound together meaning the first two suggest based on one component you need to move it from 17th of April till 1st of June it’s the same on the other component actually and this the latest delay will move my assembly order from 18th of April till 2nd of June and if I’m looking at my sales items sales orders for the same item this will also be moved based on my assembly order components that moves the assembly order that moves the sales orders so, carrying out action on this one will actually move rather few orders.

There’s also different if the assembly item is a sample to stock or a sample to order so, I know that my item 3400 is an assembly to order item and thereby if I carry out on those line it’s only the sales order that actually moves whereas if it was the other item the item 3300 here there is no direct connection between the assembly order and the sales order therefore it will be carried out separately.

So, but you need to understand the hierarchy of the assembly order.