When I calculate critical items to find critical item with the Reverse Planning, I can use calculation type end date or lead time or rolled up lead time.

Let’s say today is 25th of February and I’m running it as of today with end date for the full year.

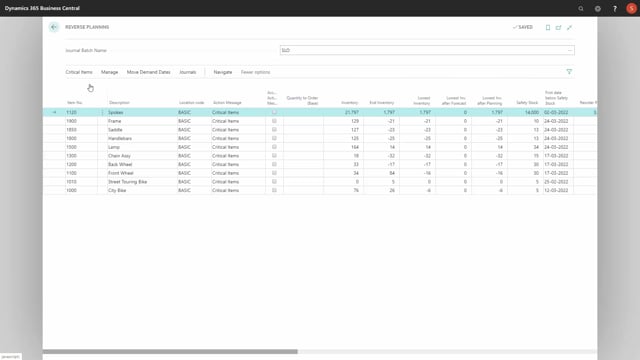

When I calculate this plan, it will come up with whatever items on the list.

For example, item 1600, 1700, 1300, etc.

And these are all my items that are critical within this period.

And some of them, for instance, if we’re looking at 1600, is critical from safety staff breach on the 12th of April.

But if I’m looking at the lead time for that item and the rolled up lead time, let me just show you here, I can see that on location code basic, and this is a calculation that you do separately on the location code basic, the lead time is six week equals 42 day.

AlSo, as a rolled up lead time, this is a purchase item.

So, this has a lead time of 42 days.

Whereas if I’m looking at my item 1300 down here, and I look at the rolled up lead times in here, be aware here that on item 1300, the lead time is one day, the directly time because it’s a production item and it’s easy to produce, but the rolled up lead time is 22 days, meaning if I’m supposed to acquire all the purchase components for this item, the rolled up lead time is 22 days.

This means if I’m running the same batch with filter on rolled up lead time instead of just end date, like this, it will change the lead time for each item according to its rolled up lead time.

This is my item 1300 will be calculated 22 days ahead and my item 1600 will be calculated 42 days ahead from the 25th of February.

Thereby my item list is shortened because the item number 1600 was not in that period now.

Likewise, if I’m calculating on directly time instead of rolled up lead time, I can see now on the backend, my item 1300 is still here because it’s within the rolled up lead time, but the directly time was only one day, meaning now I’m looking at the directly time per item.

This is the only item that are critical.

So, this way I can reduce my quantity of lines by looking, planning only within lead time or rolled up lead time.