Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inWith the Reverse Planning app comes a field on the item card that we have named move order due dates.

This is a field to create slack between orders.

Let’s see how it works.

In this scenario, on my item 1110, it’s not filled in.

And we will try to run a complete move demand date functionality here within whatever period, whatever filters, and it will suggest moving a lot of demands into the future because the supplies cannot fulfill the demand.

We have done everything we could on the purchase side.

Let’s see how this works.

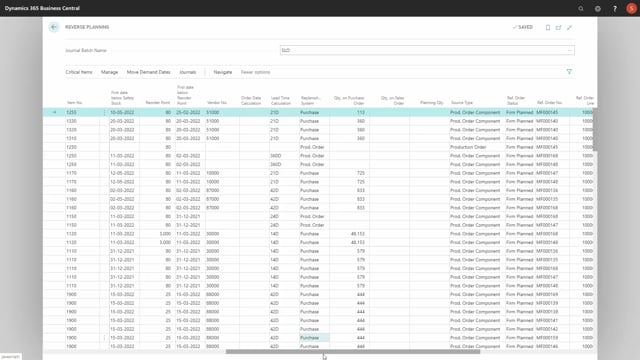

First of all, it suggests a lot of lines, and we will just take one example here.

I will filter on a firm plan production order to show the example.

And on this order, we have like eight components being critical related to the production items.

So, if I scroll right, I can see the last line.

This is the production order, the firm plan production order that we need to postpone from 10th of April till 16th of July.

You need to remember those dates now to see the difference.

So, from 10th of April till 16th of July.

On my item 1110 and my item 1250, the new due date is 16th of July.

Let’s try to add on those items the move order demand dates.

So, first of all, we will take the item 1250, and I might want to move the order date five days to create some gap between my demand and supplies.

And on the item 1110, let’s try to move it two weeks to have some dates we can really find here.

So, this means create gap between those lines.

Back in the reverse journal, and we remember the new due date 16th of June on the first one and 16th of June and the second one, and the last one being in July.

So, I’ll just calculate everything again.

I’ll just leave the filter on my production order.

It would still calculate down through the complete hierarchy and change all of the lines.

Just maintains the filter when it’s done.

And here we are.

So, now we can see that the item 1250 has been moved.

There was already a safety stock of one day, and therefore it only seems to be moving four days.

And likewise on my item 1110, it moved two weeks, and therefore on my top level item, it’s moved till the 29th of July.

That’s meaning the two weeks, of course.

So, this means when I carry out the actions on this one, and this will all relate to the same production order, therefore it will only create one line in the quick journal, rescheduling from 10th of April until 29th of July.

So, if I carry out on this one, I have slack between my orders in the hierarchy.

So, this is the functionality to postpone the orders, to create slack, and then with the dampener functionality, it’s possible if you also use the MRP planning, not to get a reschedule of those lines again.