Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inIn our experience, the MRP planning is very difficult for many customers to use. And actually, the MRP planning is a very cool tool. So once you get it, get on top of it and make all your data correct, it’s very cool. And you can do a lot of stuff with it. But often, the customer never gets to that because they have lots of data that needs to be handled and maintained all the time. Let’s take an example.

If I’m running the MRP planning here, I’ve built in a simple error here by removing the certification of a bill of material. So this is a typical error we see with our customer, somebody’s building on a new bill of material that is applied to an item which has a replenishment method, and you need to fix that to make it run. Whereas if you run the and then it stopped here by this item. Whereas if I run the reverse planning, it’s only looking at the simple math.

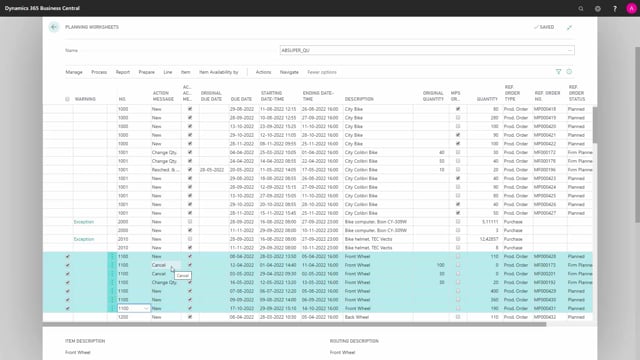

So it’s not a very complex. The MRP planning is complex. And it’s cool because it does a lot of intelligence, but it also requires a lot of setup. So here you can see my item number 1100 that I got the error on. It’s actually planned here just by saying, this is your stock, this is your end inventory, this is your lowest inventory, do something. Whereas the MRP planning would suggest what to do based on all different kinds of parameters.

So let’s try to certify the production bill of material that I have changed certification on. And then I know on this scenario, I have fixed all the potential bugs and now it should run through. And the problem is in the MRP planning, the user will also get many different action messages. And if you create your orders and you clean up everything, and you need, you move a demand one date or you move a supply a few dates, they will pop up again with many different action messages. So it’s possible to do cool. I would believe I could do the MRP planning very cool, but I’ve worked with this for 20 years. And it is very complex to understand. So if you’re not a skilled production planner, the MRP planning worksheet could be very difficult to overview. Here you can see now my items popping up with many lies on this item number. And what should we do with the cancellation? What should we do with the change quantities? Should we actually delete those orders here, the production order, change this one and create new or what should we do? So the understanding of those data is difficult for many planners.