In this video, I will try to explain the functionality show hierarchy, which can be quite complex to understand, and it relates to the move demand dates functionality.

So, first of all, I will calculate moving demand dates for all my demands when my supply side doesn’t get better.

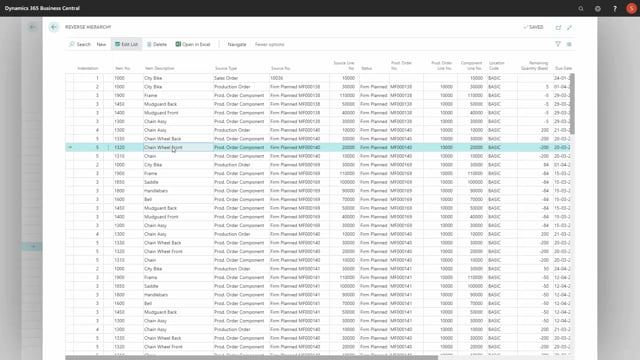

This is I’m starting low level code in the bottom and then calculating up to figure out which demands to move.

So, my first item in the calculation will be the bottom level item.

Therefore, if I show the hierarchy on those items, I wouldn’t expect anything to be in here.

If I scroll further down, I could see that they will have some impact.

The top item will have impact on the low level orders.

So, if I’m navigating on the bottom of the hierarchy, but still in the hierarchy, I can see that this backup is moved due to the socket back.

So, they are all relating to the same production order.

This is the production order and the socket back is the company.

So, there’s a direct relation.

Now if I’m scrolling further down to my item 1200 as an example, I can see different scenarios.

So, on the first line, and those are production orders that I would like to move on the first production order number 136 here.

If I’m looking at the hierarchy for that one, I can see that we only have one level, only one production order, 136 here.

This is that it’s only the tire and the rim that are postponing this back wheel.

So, according to other demands, we should be able to fulfill the demands for this production order for the back wheel.

Whereas, if I’m taking the next one, which has some other dates that it needs to be moved from until this one starts in May 16 and needs to be moved somewhere in July.

And if I’m navigating on that hierarchy, I can see both the related production order, but also another production order, order number 45.

So, if I’m looking at my indentation, I have the back wheel and the back wheel is moved due to something with the back hub, the tube, the spoke and the rim.

Those are all the components from my top level order.

But the back hub in this scenario is moved due to a production order that we need to move on the back hub.

So, whereas the previous order on item 1200 I was looking at didn’t miss the back hub, this one lacks the back hub as well.

And therefore, those could be part of the critical items on this hierarchy.

So, it’s not bound by any reservation, it’s only simple math trying to calculate which component could be part of this movement in the header.

And it turns of course more and more complex the further down you get.

So, if we’re getting down to production order on top level item 1000 in this scenario, and we view the hierarchy on this one, again, it could be a simple hierarchy if it’s on the due date only lacks some components for this item.

Or if we take the next production order here on the same item number, but this one actually has the same due date, but because we don’t have enough for both of them, the second one will be moved to another date, and thereby the hierarchy could be different.

In this scenario, it’s a little more complex, but not much.

So, this is all the component that could have effect on the movement on the top level item, but not necessarily.

And likewise, if I’m looking at a sales order down here, and I navigate into that one, it gets very difficult to say which item in the complete hierarchy is actually due to this.

Because if you’re looking at the chain wheel front further far down in the hierarchy, is this one meant for that top level item, or is it meant for other top level items? so, the higher you get in the hierarchy, the more complex the combinations are, and therefore you need of course to look into those components.

On the right hand side of this view, we have the move production order days, which displays the days that we need to move an order due to the components.

This is a very nice tool for figuring out which purchase item that creates most noise in our scenario.

So, if I’m looking here at my purchase items only, like this, and I might want to filter on the most impacting purchase items, I could place a filter on the move dates.

Let’s say, do we have anything more than 50 days for instance, and I can see all the purchase items here that we need to move more than 50 days.

Some of them here are peaking on 92 days, and those might be the first one I need to attack to figuring out what is happening on this purchase item here.

That’s my rim, could we do it better, etc.