Having the suggestion to move demand dates on production order can be rather tricky to understand.

Let’s look at that on an example.

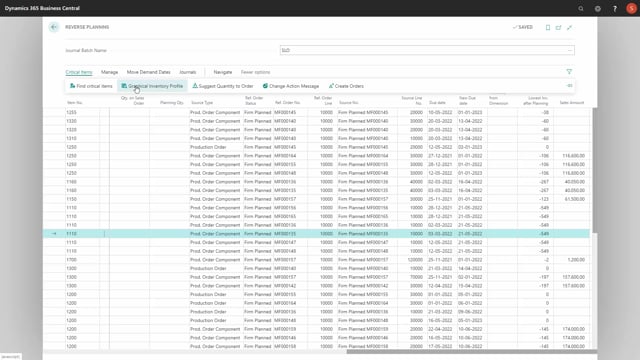

For instance, item number 1110 here, we have six lines, and if we scroll right, we can see it refers to different production orders, Fab Plan production orders, and we can look at the profile for this item to try to understand why it’s doing like it’s doing, and why it’s connected to other lines, and what it means that it’s a production order component.

First of all, let’s look at the graphical profile for this item to understand the scenario here.

Like this.

As we can see, we have some production order component demands that makes the inventory go below zero, and of course we would like the system to move those component lines to the date over here, somewhere in May, where it’s possible to actually move the item.

So, this is the scenario.

But if we look at one of the lines, let’s take the line on order number 135, and we filter to this value, we have other lines on the same production order.

So, in this example, we have a line called a production order, and two lines called production component on the same production order number.

If we look at the production order, we can navigate directly into the document.

It means that we have a production order line with item number 1100, 200 pieces, with a starting date, an ending date, and due date.

And on the production order, we do have components, and there could be a lot of components, in this scenario only five.

And the scenario is that some of those components is postponing the order, because it’s not possible to deliver on time.

And that’s the rim, the first item, and it’s the tire, the fourth item.

So, if we go back to the lines in the Reverse Planning journal, the item number 1160 is postponing or suggesting to postpone the production order from March 3 till April 16, whereas the rim is suggesting to postpone from March 3 till May 21.

And of course, if there has been other component on the production order postponing the production order, they will be listed in here.

But those are the only two that we cannot deliver on time, and when we calculate further down in the low-level code hierarchy, and we get to the top item on the production order, meaning the production order line, and this is why it’s called production order in the source type, whereas the others were components.

So, if we’re looking at the production order, it suggests that we move from March 21 till June 8.

And that’s the lead time on the production order taken from the latest of the due date that it suggests to move.

So, of course, one item could be both a production order if it refers like this to the production order line, or it could be a component in other views.

So, if we remove the filter again, like this, and we are looking only on item number 1100, like this, we could see when we scroll out that first of all it looks at item number 1100 as a production order, meaning as a supply that we are going to move, and after that calculating when is the item number 1100 a demand on other production order that makes the top-level item, meaning the bikes, etc., being moved.

So, therefore it calculates this way.

And therefore the lines for the same production order number is combined, so, if we checkmark the move order date on a line here, it will also checkmark the other lines on the same production order number.

So, it’s not possible to checkmark one line without checkmarking all of the lines related to the same production order.

And this means when I carry out action, it creates one line per production order and move related to the top-level, the production order line.

So, it reschedules based on the item number, but the date is coming from the component with the most delay.

So, this is how to understand production order movements.