One of the issues running MRP planning is that it only calculates backwards, and we don’t have a function for handling purchase items or production items when it doesn’t get better, so to say.

Let’s take an example in here. If I’m opening a planning worksheet and I’ve made a database here and a theoretical scenario where I have no lines in my planning journal, this means I’m calculating for a complete year and I’m calculating items up to number 3,000, and I’m calculating one location, and I know that I have a lot of orders, a lot of demands, a lot of everything in this location.

I’ll get back to that, but as you can see now, I’m calculating a full MRP plan, all low-level codes for those items to see what pops up. And because my data is very good and I have optimized everything and I’ve done my job, there’s actually no lines in the journal. Now the problem is this. If I’m opening my item list and there’s a vendor calling me and say we have a delivery problem.

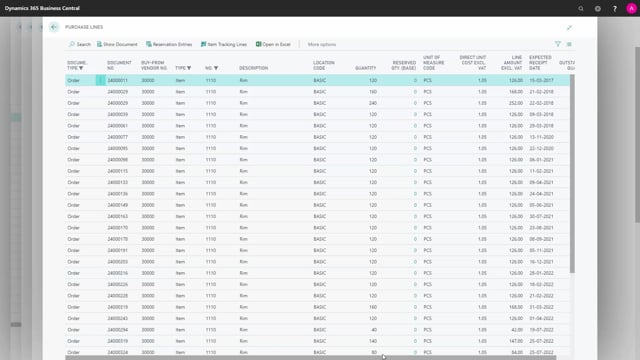

So let’s look at item number 1110, the rim, and I have on purchase orders more than 1,000 on purchase orders, and if I look into those and I’m filtering on my outstanding quantity, we will only see the lines with actual outstanding quantity, like this. So now the vendor is calling me and tells me I’m sorry, but the two first shipments from March and April, we cannot deliver those, or at least it would be very expensive if we should deliver those. So what can we do? I’m discussing with the vendor and we are considering changing this till the 20th of May. So what will happen now? Let’s try to change those two documents and maybe I want to remember the date to take it back afterwards, but I’ll need to know the consequences of changing this. So I’m opening my purchase line and I’m trying to find the specific item in here.

And I will just find my expected shipment date out here and change it to May 20, on the first one like this, and on the second order because it might be have been two orders that we cannot deliver. So after doing this, the MRP plan can’t help me anymore. Let’s try to take the second order here and we have the expected receipt date somewhere out here and we will change it till May 20, like the first one. So now we have changed two of our expected supplies to be somewhere in May on those two purchase order. What happens when we run the MRP now?

Let’s try to do that. We’ll run it exactly with the same criteria, so full year, all the same items, same location, filter everything and let’s see what’s happening. Now the problem is the MRP will calculate backwards and say what you need to do is to move the purchase demand back.

So you need to move the two purchase line back to the original days because that was part of the plan. But in real life, my problem is that the vendor cannot deliver on those dates. I need to handle it somewhere else. So it only makes line on this item number and it doesn’t matter how many times I’m trying to change it forward and backward, it won’t affect the top level item. But the problem is I need to calculate the other way. I need to calculate bottom up and that’s an issue I can solve with the Reverse Planning.

So if I have the Reverse Planning journal in here and we use the move demand date functionality and we use this functionality when it doesn’t get better. So I have the same date interval, I’m just calculating now bottom up, trying to move the items, I’m calculating on the same filters for items and locations and I will calculate per location like this.

So what we’re doing now is figuring out consequences for not being able to ship the goods that we have. And in real life we could see now that all those lines here are created from my line 1110, meaning because I delayed my purchase order, these are the consequences. This is not possible to catch or to see with the normal MRP planning.