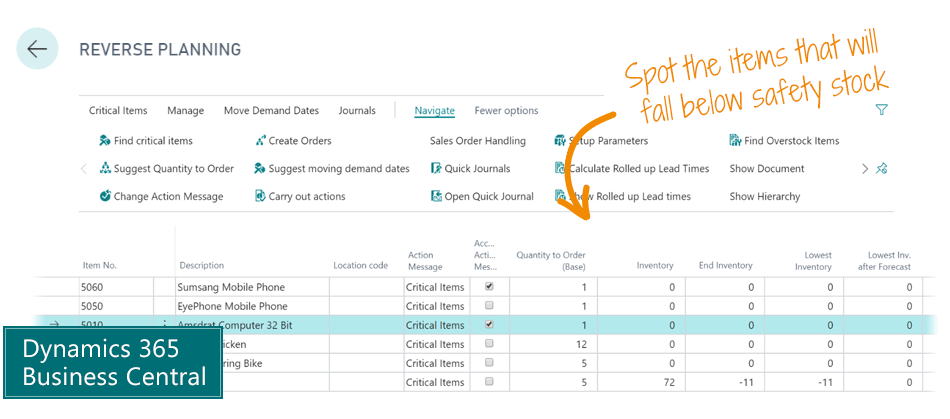

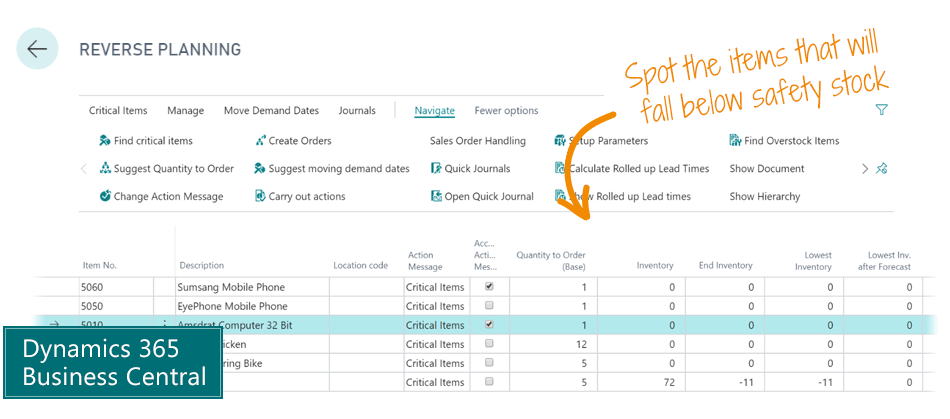

Reverse Planning

With this app you can see which items in Business Central that cannot be delivered within the lead time or a certain date, and Reverse Planning suggests actions based on all known supplies and demands.

With this app you can see which items in Business Central that cannot be delivered within the lead time or a certain date, and Reverse Planning suggests actions based on all known supplies and demands.