Playlists Manage

Log in to create a playlist or see your existing playlists.

Log inHow do you count per counting period?

Let’s look at the physical inventory orders when you calculate per counting period. First of all, let’s look at the item card to figure out what the counting period is and how it needs to be set up.

This is what happens in the video

You have a physical inventory counting period that you can set up on the item card or on the SKU card per location if you’re counting on different locations.

You can set up a frequency on how often to count it. In the scenario, the slow will be every year, the normal would be two times a year, and the fast one six times a year.

You can see the last physical inventory date.

This is the first of January 2020 and you can see the last counting update and the next counting period.

So, this item would start in first of January 2020.

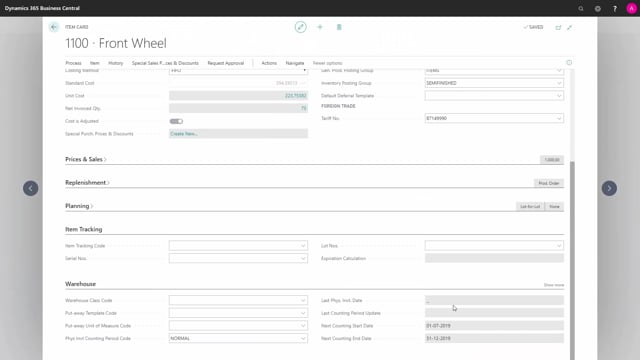

Whereas if I look at another item, let’s take item number 1100 as an example in here, and I look at my warehouse tab, there is no last physical date, meaning it hasn’t been counted with the counting job.

So, let’s try to create a physical inventory counting order in here.

And you’re on location code main and I like to calculate per counting period, meaning counting the items that haven’t been counting in the period we’re in and by the way, I’m going to post it on first of January, 2020.

I’m calculating per period and I’m getting a list of the items that needs to be calculated.

So, note that the item 1500 that we were looking upon is not on this list because it’s already counted in the period we’re in.

So, in this scenario, I’ll just select one item like this, and I would like to count this one item.

So, I’m making a new recording like this, navigate into the recording and I’ll do the counting.

Of course, I would print this document for my warehouse employee, make them find the item on inventory on the bin codes, do the counting, update the quantities, finish the inventory counting, fill in the information on the header of course.

Now, it’s finished then it’s possible to finish the physical inventory order, and normally, you can do many recordings for one inventory order.

I’m finishing it and I’m posting it like this.

So, this will post my inventory countings.

I didn’t do any changes to the inventory because everything was correct, but now I can see on my item card, I have updated my last physical inventory dates and it calculated the next counting start date based on the counting period frequency.

So, in this way, it’s possible for me to control which item has been counted when and it’s possible not to do too many countings for items that I already counted.