How do Movements, Replenishments and Countings work?

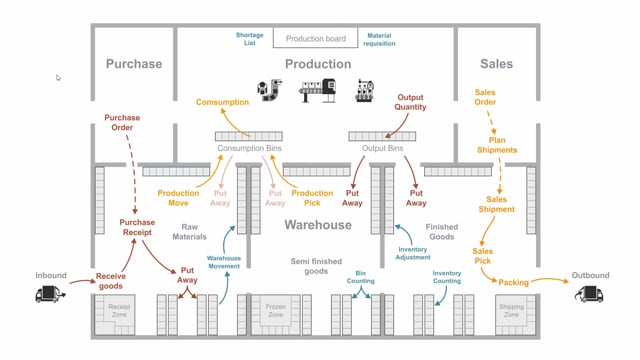

Let’s take a view at the normal processes you would like to perform in a warehouse internally. So basically, in a warehouse, when we’re not talking about the inbound and outbound side, but internally on the warehouse, we would like to do warehouse movements, meaning moving item from one bin to another bin and movement could actually be done with, of course, warehouse movements of different kinds, but also from internal put away and internal pick if we’re able to create those.

This is what happens in the video

Those actually are control of movement document also and we can do that without source documents if we have the full warehouse.

Beside movements, we would like to do bin replenishment, meaning we would like to refill, pick bins, or bin closer to the high running zones.

We could do that by bin replenishment in the functionality in different ways.

We can also do break bulks on bin, meaning to break one unit of measure down to another unit of measure on a bin in the warehouse.

That’s also only possible with the directed put away and pick checkmark, but that’s common processes in the warehouse.

Then we, of course, would like to do countings to make sure our inventory is correct.

We could do a bin counting for counting a single bin or we could do a normal inventory adjustment if we break something or find something that was missing and we can do controlled inventory countings of different kinds and different strategies.

And the last thing we might want to do, it’s a little seldom, of course, but we could also do inventory reevaluation.

This is a task that is often performed by the finance department, but it could also be a responsibility of the warehouse to reevaluate items that have been too long in inventory and would like to write off some of those so they don’t represent so high value.

That is sometimes handed over to inventory or warehouse people as well.