How does inbound warehouse work with bins and picks?

I will show you an inbound warehouse flow in Business Central that looks like this, meaning with a location where there’s a checkmark in require put-away and require bin, but there’s no checkmark in require warehouse receive, meaning we will create the inventory put-away directly from the purchase order. Let’s see how it looks.

This is what happens in the video

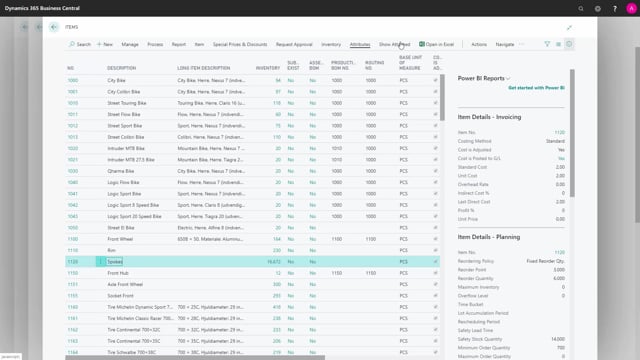

I have prepared a purchase order here, with two lines on a location code called distribute has a checkmark in require put-away and require bins and before I could handle it I need to release it. So let’s just try to create the inventory put-away without doing it. It will tell me you need to release the document because releasing the document creates the warehouse request which is now on the hidden table, meaning when I now create my inventory put-away.

It’s actually possible here. I could create the inventory put-away document. Press okay, and this creates a document for me that I can use for the handling. Let’s try to find the document we just made. It’s an inventory put-away. Here it is, and it relates to my purchase order number.

I open the document in here, and I can see the two lines, and I can print the document here to see how to have a document that I can use in the warehouse.

I need to fill in the bin code directly here, so I can place the item while I go along or enter it manually, and then I enter my quantity to handle; I will place all the quantities in those two bins, one of them a carton – be aware of this one, and the other one is in pieces, two pieces, eight pieces. After doing that I update my document here and I post the document.

And I would only receive it if I’m both receiving and invoicing now, it will actually invoice my purchase order and since I didn’t fill in the external document number, I will have an error there.

Now there was no inventory put-away documents. I have my purchase order. I can see the quantity received, there’s 2 and 8, and if I want to see what actually happened I could open the item card, or the posted purchase received or whatever and look at the entries if I’m going to the item card.

And looking into my item ledger entries, I can see here the distribute location, the quantity of 50 which was the two packages, I was receiving entered in here. And it also creates warehouse entries, of course directly with the inventory put-away.

So, this is how it works using the require put-away and require bin fields.