How do you use pre-movement to the production area?

If I’m using location with require shipment, which means that I have to create a warehouse pick for production orders, I have the problem that sometimes I might want to pick more than required for the production order.

This is what happens in the video

And why would I do that? Well, let’s look at this item number for an example that I’ve prepared, if I’m looking at the bin contents for this item number, my normal pick bin will be 11.06 and I have 24 pieces here, but I have moved 10 pieces into a bin which is not a production bin, but it’s placed in my production area.

And the reason for that could be that I will handle a full box of 10 pieces and not start to take out some of the pieces in the inventory.

Maybe it’s a production order where I’m not quite sure of the consumption quantities and output quantities because I have a lot of slack on that.

It could be the reason that I have a big pallet of items that I’d like to roll into the production area and make the production people consume from it and then we move the rest back again.

Either way, I would like to make a movement into production before actually doing the consumptions.

Let’s just take this as an overview in PowerPoint.

So, the scenario is maybe I have a production bin called 120, which means that I have to make my production consumption from a bin in there.

So I need to do a warehouse pick into bin number 120 but prior to that, I would like to do either a warehouse internal pick or a warehouse movement to actually move the full quantity into one of my sub bins, which is not set up as production bin, but as put pick bins.

So, in this scenario, I would like to move items into bin number 120.08 and then to create my warehouse pick from there. Let’s go back in Business Central to see how it looks.

So, going into my production order, which for right now hasn’t consumed anything, meaning I have no entries in here. I haven’t created any pick or anything.

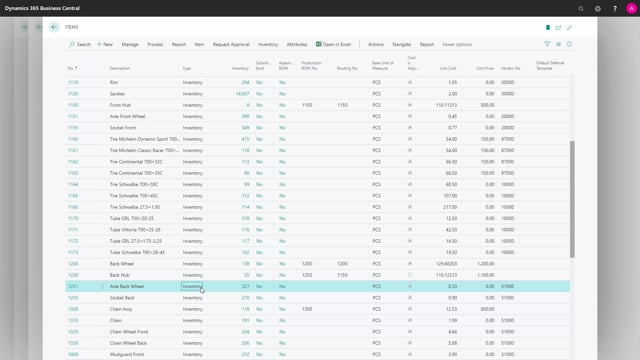

On my component line, I can see that I need two different components, and the first one, my 12.51, I would like to roll into the production area with quantity 10.

So I already did the movement and I just need to be aware now that on my production order when I create my warehouse pick like this, there will be one issue of this strategy that I need to be aware of. I will go into the warehouse pick.

And now that’s suggested of course because there will only be one default pick bin and normally I might want to pick this to a sales order or other demands and therefore, my default pick bin code will be 11.06.

And so, I cannot make my production bin the primary one if I’m primarily picking to other bins.

Now the problem is, I need to pick four and if I drill down into my bin code here, I cannot see my bin 120 because my zone code might be set up differently.

So, I need to be aware to delete my zone to be able to drill down the bin code to see all the bins and here is my bin that I need to pick from.

So now I’m done and ready to post my warehouse pick– register the warehouse pick that registers the item into my bin 120 from which I can do the consumption.

This means the production people if I’m using zone will have to be aware of deleting the zone when creating warehouse pick if you follow this strategy.