What do you use the Warehouse Physical Inventory Journal for?

If I’m working on a location with a checkmark in the directed put away and pick on the location card, I would need to use the warehouse physical journal to do the inventory counting. I cannot use a normal physical item journal. So, I use the warehouse physical journal and I need to synchronize it after counting.

This is what happens in the video

In the warehouse physical inventory journal, it’s possible to calculate the existing inventory right now based on my warehouse entries and I will do this on only one item for the example.

Otherwise, I’ll get too many lines in here.

So, I can enter the item number or I could filter by bin or by lots of other stuff, I’ll show you afterwards. It displays the calculated quantity, but not the counted quantity. So, it meant to be actually be entered in here. Meaning you cannot pre-fill the physical inventory quantity.

So, when you run directed put away, the meaning is that you have to count your inventory. So, I will enter here what I’m actually counting maybe I only have 2. 5 of this one and 5 of the other one, but only 9 on that bin. And of course, I’m doing this after actually printing this document.

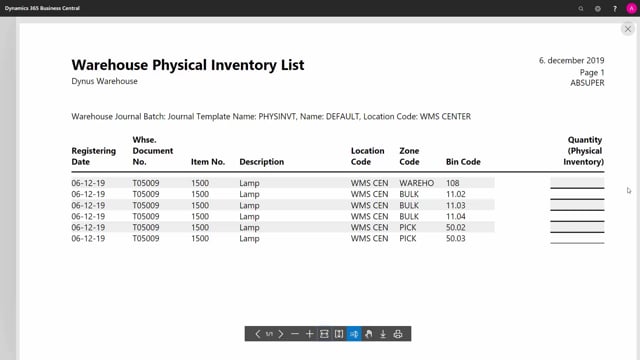

Normally, I would print it to my warehouse employee and it looks like this and this will be printed out and you can use this for walking around your inventory actually counting per item, per bin, and entering the physical quantity in the column on the right-hand side and after that, we are entering the quantity back in the journal.

So, let’s say we have 10 of this one but maybe 14 of this and it makes a positive warehouse entry and only 5 of the last one.

So, the quantity field will be the differences we’re going to post.

I could also, when I actually calculated the inventory, I could have filtered on zones and bins and items, unit of measure, etc, etc.

And we will show that in other videos on how to do detailed calculation per rack or bin or whatever.

So, this is a very smart tool to count per bin instead of per item.

After entering all the calculated quantities, I just need to process my journal and register it.

So, this will register changes to my inventory and I have to remember how to synchronize it up against my items using the item journal, the normal item journal and the functionality to calculate warehouse adjustments that I just did.

And these adjustments are the changes from the calculated quantities to my final countings and I need to post that of course into my item journals.

So now I have changed both my warehouse entries first and afterwards my item ledger entries.