How is the Outbound Warehouse flow with Bins and Picks required?

I will show you a complete flow in Business Central with the location that requires bins and picks but no warehouse shipment and therefore also no directed put away and the flow will reflect what you can see on the screen meaning I will create a sales order, release it, create an inventory pick, perform the pick and register it.

This is what happens in the video

Let’s see how it works in Business Central.

Before creating a new sales order, I will just show you the location set up that we’re working on.

The location that’s the distribute location has a checkmark in require pick and bin mandatory.

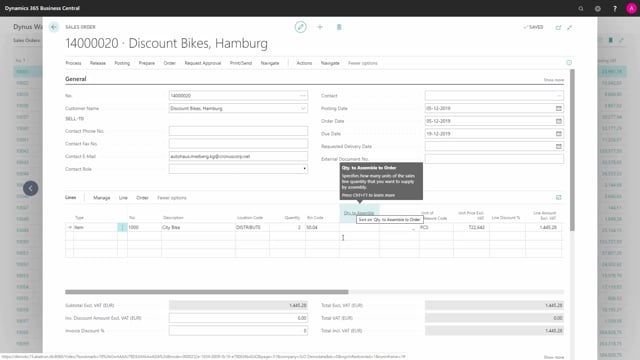

First of all, I will create a new sales order.

And be aware, in this scenario, when I enter my item number, it’s actually possible on this location code to enter quantity directly on the sales line without creating a pick changing the bin code.

So this is the fast way of actually creating the order if I’m not going to perform the pick.

So with this scenario, this is possible.

I’ll just ship my sales invoice here and everything worked correctly.

I have shipped with my quantity on the correct bin code.

So this is one way of not using the pick with that location set up.

So the scenario we had in the PowerPoint overview would be like this.

I will enter two item lines with different numbers, different quantities like this and from my sales order, I could create a pick but I need to release it meaning if I’m just going into my action and creating a warehouse pick, I will get an error message.

So working with warehouse documents, we need to release our order documents.

Release and then create inventory pick.

Here we are.

So now we have created a pick.

I can navigate into the pick directly from my sales order or I could just open the pick from my Business Central menu.

Here’s the pick document.

Be aware there’s only two lines because I just need to go and fit the item on those two bin codes.

I could change the bin code here even before or after picking it.

So let’s just try to change it like this and I could print a picking note if I’m not using handheld scanner device.

So it’s possible to print from here.

And I’ll view my picking note here displaying the two bins that I’ve added, the quantity, and I can fill in here the quantity handled and even if I’m changing the bin code, I will just enter it directly on the paper while working around on my warehouse.

After printing my pick, I will do the pick, perform the pick and maybe I use some other bin codes for some reason or took the item all the way and I’ve entered that on the paper and then I need to enter on the lines the actual quantity that I have handled like a confirmation.

I could have pre-filled that or I could have used the functionality of auto-fill quantity to handle but normally you would do that by hand if you want to make sure it’s correct and then I can post the document.

And because it’s an inventory pick, it will actually ship the sales order when I’m posting it.

So now my pick is automatically deleted, changed into a posted pick, and I can see on my sales order line here that I have shipped the quantity 8 and 4 and, of course, shipped it on the bins that I’ve entered.